A staple of the winter Olympics, the biathlon combines cross-country skiing and rifle shooting. Mastering both of those disciplines sufficiently to compete at an international level is no mean feat. Achieving that while living with spina bifida is truly remarkable. Despite his condition, German athlete Martin Fleig started practicing this sport at age 9. Although he was "initially disheartened," his mother encouraged him to keep at it. Now 24, Fleig is headed for Sochi, Russia, where he will compete in the 2014 Paralympic Games.

January 30, 2014

A staple of the winter Olympics, the biathlon combines cross-country skiing and rifle shooting. Mastering both of those disciplines sufficiently to compete at an international level is no mean feat. Achieving that while living with spina bifida is truly remarkable. Despite his condition, German athlete Martin Fleig started practicing this sport at age 9. Although he was "initially disheartened," his mother encouraged him to keep at it. Now 24, Fleig is headed for Sochi, Russia, where he will compete in the 2014 Paralympic Games. In addition to his tenacity and fortitude, Fleig will be bringing a custom-designed sit ski developed specifically for his anatomy by the Fraunhofer Institute for Mechanics of Materials IWM (Freiburg, Germany) and industrial and research partners working within the Snowstorm project.

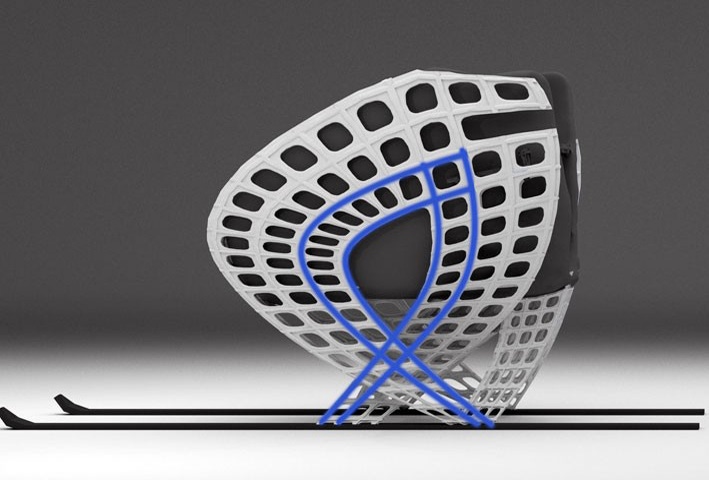

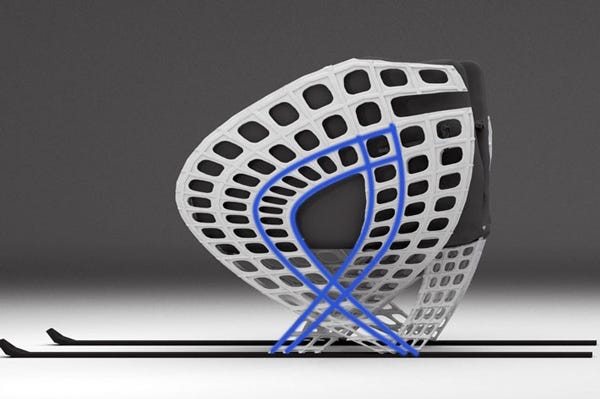

Sit skis typically have a seat mounted on at least one of the skis. Snowstorm was established to design, develop, and manufacture custom sit skis for disabled athletes in a cost-efficient manner. Additive manufacturing, also known as 3D printing, plays a central role. Fleig volunteered to have the group design equipment suited to his specific needs.

During a biathlon competition, skis are subject to a range of stress. In addition to gliding over nongroomed snow, the skis must withstand extreme pivotal motion, given the lightning-fast transitions between skiing and shooting postures.

Initially, biometric data of Fleig's movements were captured to ascertain the optimal seating position. Fraunhofer scientists then ran a number of computer simulations to determine an appropriate lightweight ski design. Although the goal in this instance was to come up with a custom design for Fleig, the project's ultimate objective is to find a technique for designing sit skis that can be cost-effectively tailored to any athlete. A key enabling technology is additive manufacturing, specifically laser sintering.

A prototype of the sit ski was made using polyamide 12 embedded with sensors to measure material stress during use. The ski poles also contained sensors to record force. This data informed the design of a second prototype, where channels were incorporated at the points where the highest stress levels were recorded. These channels were then fitted with steel wires for reinforcement.

Fleig has put the new sit ski through rounds of endurance tests in Germany's Black Forest and the Italian Alps. Next stop: Sochi.

About the Author(s)

You May Also Like