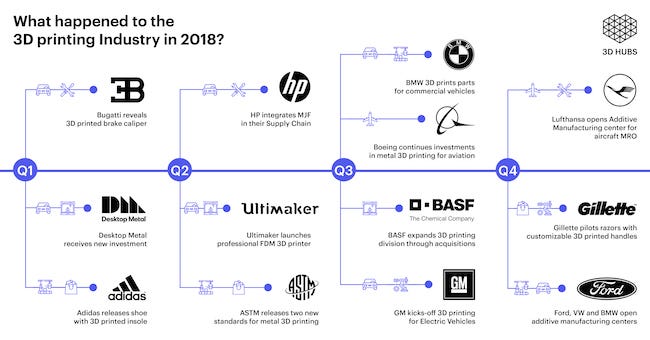

A capsule summary of industry milestones in 2018 and forecast of future opportunities and challenges.

March 13, 2019

Three-quarters of the major automakers in the United States and Germany currently use 3D printing to manufacture end-use parts, and the 3D printing market as a whole is forecast to grow about 23.5% over the next five years, according to a new report, 3D Printing Trends, Q1 2019.

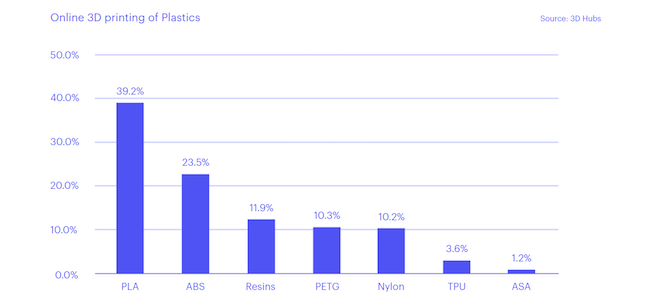

Published by 3D Hubs (New York), a global network that facilitates access to manufacturing facilities specialized in 3D printing, CNC machining and injection molding through an online platform, the report presents a capsule summary of industry milestones in 2018 and forecasts future opportunities and challenges. A substantial section is devoted to online 3D printing demand, which 3D Hubs knows well, but the report also delves into broader issues around the use of additive manufacturing for end-use applications. Here are five takeaways that I found interesting; you may find others in the report, which is now available as a free download.

|

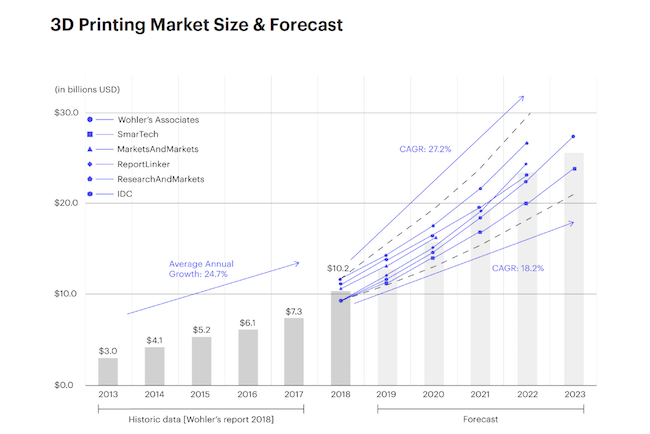

From 2013 to 2017, 3D printing grew at a rate of 24.7% on average every year, notes the report based on data from reputable sources such as Wohlers. Depending on the source, growth forecasts through 2023 vary between 18.2% and 27.2%; this averages out to a compound annual growth rate of 23.5%, meaning that the "global 3D printing market will double in size approximately every three years,” writes 3D Hubs.

|

In 2018, venture capital (VC) funding in 3D-printing-related startups exceeded $300 million, and the common thread of all of the investment activity was industrial solutions and applications. VC funding is heavily concentrated in the United States, where 80% of all 3D-printing companies have their headquarters. Moreover, a trio of 3D-printing companies—Carbon, Desktop Metal and Formlabs—accounts for approximately 80% of the total VC funding. They are currently the only “unicorns” in the industry, meaning they are valued at more than $1 billion.

The global manufacturing market is currently valued at $12.7 trillion, meaning that 3D printing represents less than 0.1% of global manufacturing, according to the report. If 3D printing manages to capture just 1% of that market—a scenario that is possible, according to many industry experts—it can reach annual revenues of $125 billion. This is five times greater than even the most optimistic five-year forecast, notes 3D Hubs.

|

The barriers to adoption for large enterprises are mainly related to social factors; for example, an understanding of the technology and education. This echoes what we have been hearing from other 3D printing experts at PlasticsToday. The unprecedented opportunities that 3D printing brings to product design are not always harnessed by engineers, many of whom have been trained in conventional production technologies. The good news, adds the 3D Hubs report, is that this will cease to be a limiting factor over time. “Early adopters see the necessary investment as an opportunity to increase their competitive offering, and once they show the way, small and medium enterprises will follow. This is the ‘slow revolution’ everyone in 3D printing is currently describing.” It is only a matter of time until “additive manufacturing is fully adopted and finds its place in the greater manufacturing ecosystem,” notes the report.

And when it does find its place, 3D printing will be in good company. It will not replace traditional manufacturing technologies, like CNC machining or injection molding, but will work alongside them to create a powerful digital manufacturing ecosystem, stresses the report.

About the Author(s)

You May Also Like