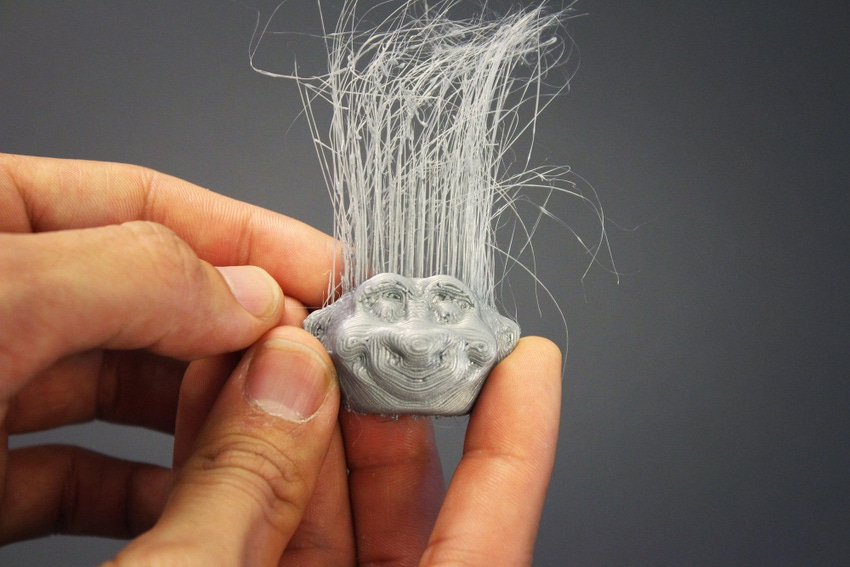

While 3D printers are typically known to produce hard plastic objects, researchers at Carnegie Mellon University have come up with a method for using inexpensive 3D printers to fabricate plastic hair—a technique they call “furbrication.”

November 2, 2015

The idea for 3D-printing hair drew inspiration from the tiny strands you get when you pull a hot-glue gun away from a gob of melted plastic. The same concept can be applied to the plastic used by a 3D printer. “You just squirt a little bit of material and pull away,” said Gierad Laput, a Ph.D. student in Carnegie Mellon’s Human-Computer Interaction Institute. “It’s a very simple idea, really.”

The idea for 3D-printing hair drew inspiration from the tiny strands you get when you pull a hot-glue gun away from a gob of melted plastic. The same concept can be applied to the plastic used by a 3D printer. “You just squirt a little bit of material and pull away,” said Gierad Laput, a Ph.D. student in Carnegie Mellon’s Human-Computer Interaction Institute. “It’s a very simple idea, really.”

The plastic hair is produced strand by strand, so the process isn't fast—it takes about 20-25 minutes to generate hair on 10 square millimeters. But it requires no special hardware, just a set of parameters that can be added to a 3D print job. The resulting hair can be cut, curled with hot air, or braided. Dense, close-cropped strands can form a brush.

Laput and his fellow colleagues have used this technique to add hair in a variety of colors to 3D-printed objects— the straight-up shock of hair on a troll head, long whiskers on a wizard that looks like Gandalf, and a tail on a horse.

The 3D-printed hair will be displayed publicly for the first time today at the Engadget Live event in Liberty Warehouse in Brooklyn, NY. Laput and his colleagues, fellow HCII Ph.D. student Xiang "Anthony" Chen and HCII Assistant Professor Chris Harrison, will present their method on Wednesday Nov. 11, at UIST 2015, the ACM User Interface Software and Technology Symposium, in Charlotte, N.C.

About the Author(s)

You May Also Like