The curtain finally lifted on two brand new additive manufacturing systems, one of which is pretty, pretty big.

October 20, 2022

Following a months-long teaser campaign, KraussMaffei finally lifted the curtain on the “something” that it had to “add.” At 4:40 p.m. local time on Oct. 19, CEO Michael Ruf spoke briefly about what was behind the curtain at booth C 24 in hall 15 before pushing the red button to reveal two new additive manufacturing machines — the precisionPrint and powerPrint systems — representing the “fourth pillar” in the company’s product portfolio of injection molding, extrusion, and reaction equipment.

|

KraussMaffei CEO Michael Ruf (center) at K 2022 gets ready to reveal the additive manufacturing systems behind the curtain. |

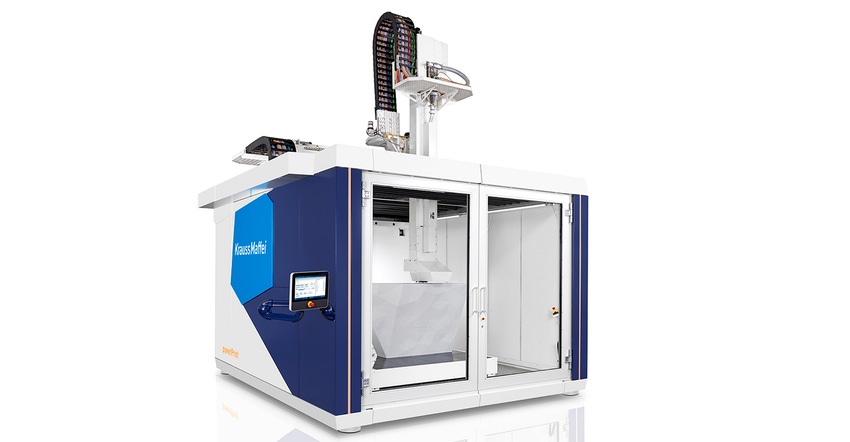

The precisionPrint is a high-performance, high-output stereolithography system suited for the cost-efficient production of plastic parts. It uses printing resins cured by laser. But it was overshadowed — literally — by the powerPoint printer (pictured in the feature image), a huge extruder-based system for processing thermoplastic granulates.

Designed for large-format (up to 10 m³) additive manufacturing, the powerPoint enables reliable, efficient production of near-net-shape components, said KraussMaffei. Optimal component properties are achieved at favorable material costs, and short setup times and the use of common software solutions for print preparation enable rapid implementation from component design to printing, according to Rolf Mack, who heads additive manufacturing at KraussMaffei. “In developing this, our goal was optimal application-specific processing of thermoplastic materials to ensure production according to industrial standards,” said Mack.

The powerPrint can process a range of fiber-reinforced plastics and compounds. It is shown producing a complexly structured component at the KraussMaffei booth. at the K show.

The precisionPrint system is less imposing from a size perspective, but it should not be underestimated from a performance point of view, according to KraussMaffei. It supports plastics processors along the entire product life cycle and opens up market opportunities for individualized products and smaller production batches. "Production with almost no material loss and great design possibilities – we bring these additive manufacturing advantages from prototyping to industrial-series production of plastic components,” said Mack.

|

The precisionPrint additive manufacturing system also debuted at K 2022. |

KraussMaffei plans to begin intensive testing of the printers with beta customers in 2023, after which the printers will be available on the market.

In addition to plastics processors, the precisionPoint and powerPoint systems will interest customers in the medical technology, building and construction, and foundry industries, where it has the potential to create new market opportunties, said KraussMaffei.

Note to nitpickers: Yes, technically, this event happened on day one of the show, so I am taking some editorial license in naming it the coolest thing we saw on day two. But the reveal happened very late in the day and an impressively large crowd was there for the curtain drop, so I couldn’t really examine the machines until day two.

K 2022 runs through Oct. 26 at Messe Düsseldorf in Düsseldorf, Germany.

About the Author(s)

You May Also Like