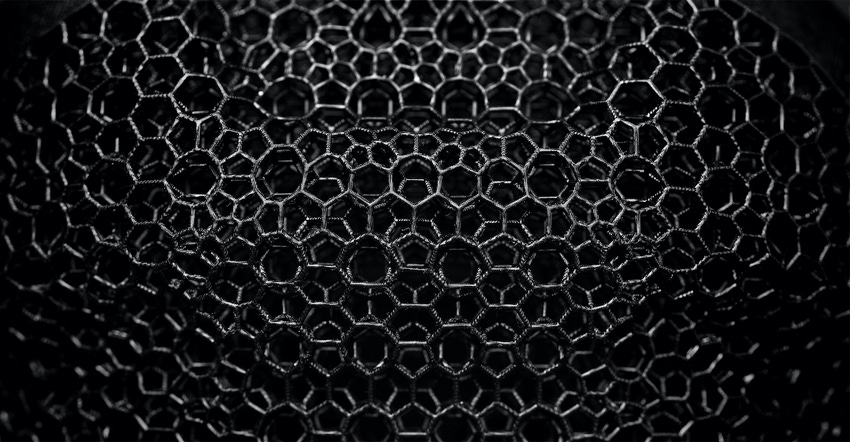

The digitally-printed, lattice-structured liner offers superior breathability, premium comfort, and elite protection.

September 15, 2020

CCM Hockey and Carbon are revolutionizing the design of hockey helmets, which have remained largely unchanged for half a century. Manufactured with Carbon Digital Light Synthesis (Carbon DLS), CCM Hockey’s Super Tacks X with NEST Tech is the world’s first hockey helmet with NEST (Next Evolution Sense Technology) — a digitally-printed, lattice-structured liner that offers superior breathability, premium comfort, and elite protection. This next-generation helmet is customized to fit an athlete's head and, with its unique lattice design, enables refined control of energy absorption and dissipation to help keep players protected.

“At Carbon, we are laser focused on enabling customers to bring innovative products to market that push industries forward,” said Carbon CEO Ellen Kullman. “We’re excited to partner with CCM Hockey, a leading manufacturer in hockey equipment for over a century, to produce a revolutionary hockey that will change the game.”

|

3D-printed hockey helmet is better at absorbing dissipating energy by aligning internal damping struts against the directions of impact that hockey players experience during play. Image: Carbon |

“Super Tacks X with NEST Tech is a revolutionary helmet liner technology, bringing unmatched breathability, superior fit, improved comfort, and elite level protection for our athletes,” says Jeff Dalzell Vice-President Product Creation, CCM Hockey. “We’re thrilled to be working collaboratively with Carbon to bring never-before-seen innovation to the hockey industry with this new helmet.”

The Super Tacks X with NEST Tech liner is produced using Carbon Design Engine software, which automatically generates an optimized lattice structure based on desired performance criteria and weight. This lattice structure facilitates the absorption and dissipation of energy by aligning internal damping struts against the directions of impact that hockey players experience during play. With over 130,000 individual struts, the lattice is built so each strut is specially tuned at every point on the helmet. Increases or decreases in the stiffness of the lattice structure are enabled through precise adjustments to the thickness of each strut, allowing the lattice to absorb and disperse energy from various impacts.

The custom-fit helmet will be available to all NHL players ahead of the 2021 season. During the 2020 NHL season, three professional players played in this helmet, including Austin Matthews (Toronto Maple Leafs), John Tavares (Toronto Maple Leafs), and Seth Jones (Columbus Blue Jackets).

Jones was wearing the helmet during Columbus’ first-round playoff game vs. Tampa Bay that went to five overtimes. The 25-year old set an NHL playoff record for most minutes played in a single game, skating for 65 minutes and six seconds.

CCM will be releasing a 3D-printed retail helmet for consumers in the spring of 2021, using some of the same advanced technology being made available to professional athletes.

About the Author(s)

You May Also Like