M. Holland will distribute selective laser sintering (SLS) materials from the partner companies to support adopters of the rapidly expanding 3D-printing technology in North America.

December 8, 2020

M. Holland Co. has partnered with Advanced Laser Materials (ALM) and EOS North America to distribute selective laser sintering (SLS) materials. The agreement marks M. Holland’s first venture in the SLS space. It will allow the distributor of thermoplastic resins and 3D-printing materials to better support OEMs and injection molders using SLS and businesses interested in adopting this technology.

The North American distribution agreement includes powdered polymers for SLS printing; several additive manufacturing materials compatible with a variety of 3D printers; and access to standard polymer materials from EOS and custom solutions developed by ALM.

“Our partnership with ALM was a natural fit,” said Haleyanne Freedman, Market Manager, 3D Printing, at M. Holland. “Offering SLS technology materials and solutions is important to broaden options for our clients, and ALM’s consultative approach complements the way we do business. ALM delivers strong customized material offerings focused on application and technical requirements, which equips us with an expanded suite of solutions and technical information to solve tough application problems for injection molders,” said Freedman.

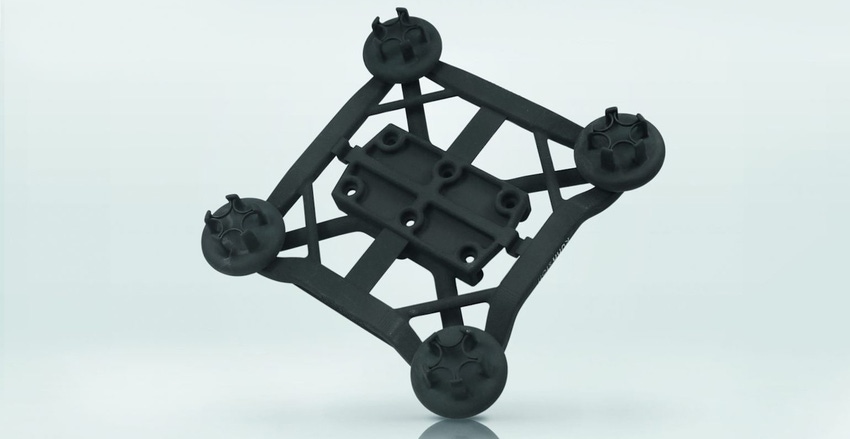

Powder-bed-based SLS is a rapidly expanding technology for production applications, explained M. Holland. The process is fast, efficient, and accurate, offering highly repeatable results that can produce large batches of parts and fine features. When it was first introduced, SLS polymer printing was primarily based on nylon. Today, polyamide (PA), polyetherketoneketone (PEKK), polypropylene (PP), thermoplastic polyurethane (TPU), thermoplastic elastomer (TPE), and other materials are typically used in SLS processes.

“Through our agreement with M. Holland’s 3D-Printing group, we are collectively broadening what is possible through selective laser sintering 3D-printing technology — reaching new markets and helping drive new applications,” said Darin Chartier, Vice President, Life Cycle Solutions, at EOS North America.

M. Holland’s 3D-printing portfolio also includes materials from Braskem, BASF, and Henkel.

About the Author(s)

You May Also Like