The Japanese company has entered into a partnership agreement with German start-up AM Polymers covering PBT powders for 3D printing; potentially replacing polyamide 12.

June 16, 2020

Mitsubishi Chemical Corporation (MCC) and German new materials start-up company, AM Polymers GmbH (AMP) have entered into an exclusive joint development and commercial partnership agreement on polybutylene terephthalate (PBT) powder product for industrial 3D printing.

|

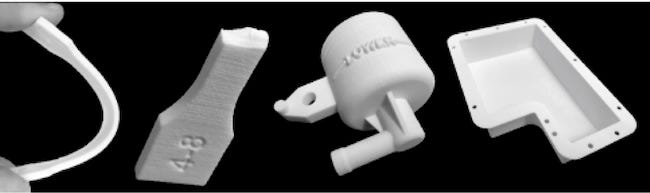

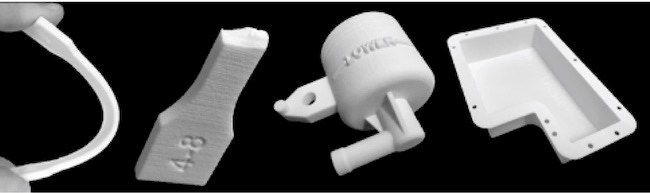

PBT 3D-printed parts including as a test piece for mechanical characterization, an automotive braking fluid pump, and an electronic control unit case. The broken specimen cross-section is proof of high ductility due to breakage across and not parallel to the layers, which is a failure mechanism similar to those found in traditional injection molding parts. Image courtesy of Mitsubishi Chemical. |

Located in Germany, AMP specializes in producing and selling thermoplastic powders with “plug & play” processability and part performance for selective laser sintering (SLS) and powder bed fusion (PBF) processes. Through this partnership, both parties are jointly developing new powder products for industrial additive manufacturing from PBT resin that has been specially optimized based on MCC’s chemical expertise. A beta version of Rolaserit PBY01 powder will be soon unveiled in Europe for client evaluation.

This partnership provides MCC and AMP an opportunity to further expand their product portfolio for 3D printing. SLS/PBF is a process by which users can achieve complex geometries at short production lead time. Coupled with good mechanical properties, PBT powder has much lower moisture absorption characteristics than polyamide 12, a common material for SLS and PBF processes. Thus, MCC and AMP expect new PBT powder products to be used for industrial applications such as automotive and aerospace. This new partnership enables MCC and AMP to further accelerate growth in the 3D printing area.

About the Author(s)

You May Also Like