Intricately patterned 3D tissue constructs with multiple types of cells and blood vessels have been produced using a bioprinting technique developed by researchers at the Wyss Institute for Biologically Inspired Engineering at Harvard University and the Harvard School of Engineering and Applied Sciences. The work represents a major step forward in creating human tissues to test drug safety and effectiveness ex vivo. It also is an early step toward building functional replacements for injured or diseased tissue at the push of a button, according to the researchers.

April 14, 2014

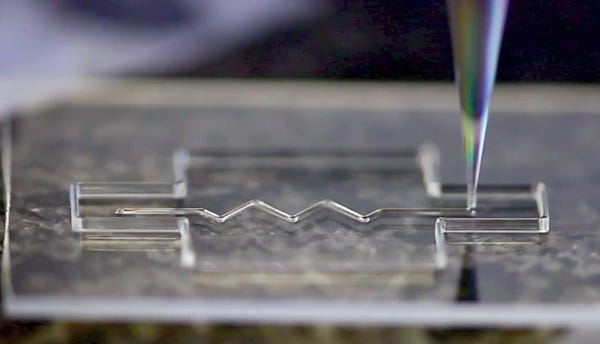

Growing vascularized human tissue in a lab has stymied researchers in the past because they have been limited to creating thin slices of tissue, about one-third the thickness of a dime. In thicker tissues, interior cells are starved of oxygen and nutrients and consequently die. Wyss researchers remedied this by developing a bio-ink to create blood vessels. The ink (pictured) has the unusual property of melting as it cools. Scientists used the ink to print a network of filaments, which melt as they cool and then suctioning out the liquid to create hollow tubes acting as blood vessels.

The 3D-printed tissue was injected with human endothelial cells, which regenerated the blood vessel lining. The immediate application is drug screening, but scientists anticipate that the tissues could shed light on wound healing, blood vessel growth, and tumor development. It also enables the possibility of surgically connecting the networks to the natural vasculature and enable immediate perfusion of the implanted tissue and increase successful grafting.

Bioprinting human tissue |

|

About the Author(s)

You May Also Like