Mitsui Chemicals and Microwave Chemical aim to commercialize technology for decomposing offcuts of foam used to manufacture car seats and mattresses.

June 22, 2022

Mitsui Chemicals and Microwave Chemical have launched a new initiative aimed at commercializing chemical recycling of flexible polyurethane (PU) foam via microwave technology. The project involves direct synthesis of PU raw materials by decomposing offcuts of the foam used to manufacture mattresses and similar items. Previously, the two firms had collaborated to develop recycling technology for automotive shredder residue (ASR). They are also working jointly to develop eco-friendly carbon-fiber manufacturing technology using microwaves.

Flexible polyurethane foam principally consists of polyols and isocyanates. Its softness and high resilience have led to a wide range of applications, from industrial goods and materials to daily necessities, including mattresses, car seats, chair cushions, and kitchen sponges. However, chemical recycling of flexible PU foam and other PU products has not yet been achieved at a commercial level in Japan. Therefore, the development and commercialization of such technology is a pressing issue from the perspective of contributing to a circular economy.

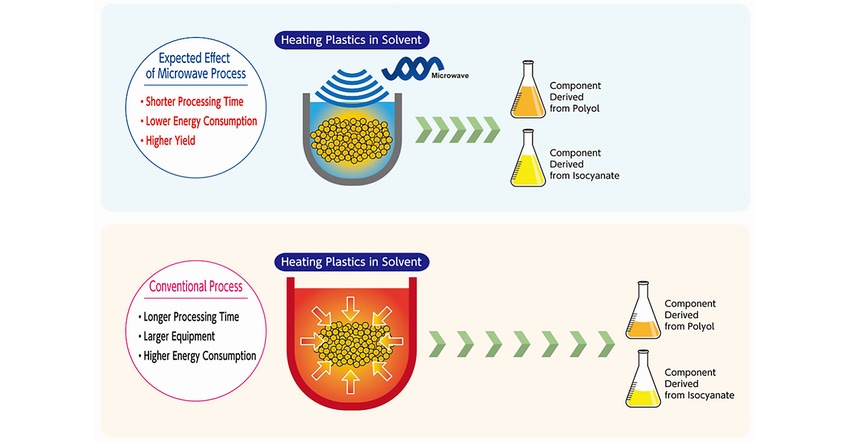

Using PlaWave microwave-based plastic decomposition technology developed by Microwave Chemical, the processing time for decomposing flexible PU foam is expected to be at least cut in half, and a substantial reduction in energy consumption compared with existing technologies is also anticipated. Microwave technology will also contribute to reducing CO2 emissions, as its efficiency will reduce costs and enable the process to be powered by electricity generated from renewable energy.

The PlaWave platform for decomposing plastic using microwaves is able to be applied both to pyrolysis and solvolysis. PlaWave enables faster reaction speeds and greater energy efficiency in a more compact device, according to the companies.

Since initial testing achieved positive results, the project will proceed to small-scale demos using Microwave Chemical’s bench-scale demonstration device by March 2023 and move on to further examination, with the objective of commencing demonstration tests in March 2024 and commercializing the technology by March 2026. In tandem with demonstration tests, Mitsui Chemicals will build a business model that encompasses the whole value chain for the recycling of flexible polyurethane foam to realize a circular economy.

About the Author(s)

You May Also Like