Dual purging demonstrations, with one for injection molding and the other for extrusion, including a color change from black to white resin, were highlighted at Asaclean's NPE2012 booth (West Hall, #3063). On a small lab-scale extruder, Asaclean is also undertaking a screw pull after running black ABS, offering attendees two rows of chairs to take in the technology first hand.

April 4, 2012

Dual purging demonstrations, with one for injection molding and the other for extrusion, including a color change from black to white resin, were highlighted at Asaclean's NPE2012 booth (West Hall, #3063). On a small lab-scale extruder, Asaclean is also undertaking a screw pull after running black ABS, offering attendees two rows of chairs to take in the technology first hand.

Asaclean

The company is highlighting its previously released PX high-temperature purging compound, which can be run from 518°F-780°F, besting any competitive offerings, according to Asaclean, by about 50°F. Asaclean's Joe Serell told PlasticsToday that it's part of an ongoing effort to keep up with high-temperature materials like PEEK. Sun Plastech's head of R&D, which works to stay ahead of that material development curve, was at the booth in Orlando, with his department actually expanding staff recently so that he has five employees dedicated to the Asaclean line.Serell told PlasticsToday that the last two years have been very good for the company, with the start of 2012 looking even better, without disclosing specific figures. Glenn Kornfeld, Asaclean's president, told PlasticsToday that a key differentiator for the company are its salespeople who hail from the plastics industry, and average 19 years of experience within plastics.

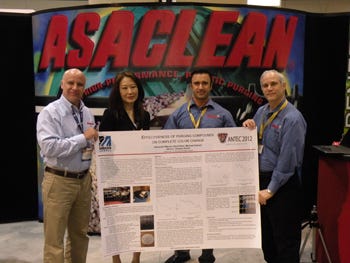

Asaclean also displayed the research work of three UMass Lowell students who undertook a study on whether it was faster to purge an injection molding machine with Asaclean or with polypropylene. Their work was presented during the concurrent student poster session at ANTEC.

The students used visual inspection and spectrophotometry to measure color change, finding that Asaclean was able to remove any color within 100 samples, while PP took more than 200, nearly four times as many.

"The study basically confirmed in a very scientific trial that Asaclean is much more effective than just using resins," Serell said.

About the Author(s)

You May Also Like