The composite, which uses mixtures of polypropylene and polyethylene with multi-wall carbon nanotubes, achieves impressive impact resistance.

February 10, 2021

A new type of 3D-printed material made by combining polyethylene and polypropylene with carbon nanotubes is tougher and lighter than similar forms of aluminum, scientists say. The plastic-carbon nanotube composite plate-lattice metamaterials belong to a class of artificially-created cellular solids, designed and engineered to manifest properties that do not occur in the natural world.

In a new paper published in the journal Materials & Design, a team led by University of Glasgow engineers describes how they developed a new plate-lattice cellular metamaterial capable of impressive impact resistance. The material could lead to the development of safer, lighter, and more durable structures for use in the aerospace, automotive, renewables, and marine industries.

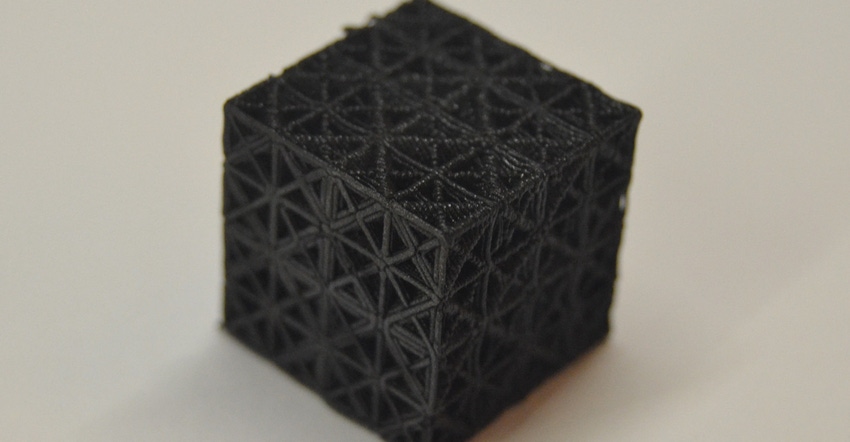

Plate-lattice metamaterials are cubic structures made from intersecting layers of plates that exhibit unusually high stiffness and strength despite a significant amount of space between the plates. Those spaces, which are a property engineers call porosity, also make plate-lattices unusually lightweight.

The researchers set out to investigate whether new forms of plate-lattice design, manufactured from a plastic-nanotube composite they developed, could make a metamaterial with even more advanced properties of stiffness, strength, and toughness.

Their composite uses mixtures of commonplace polypropylene and polyethylene with multi-wall carbon nanotubes.

The researchers used their nano-engineered filament composite as the feedstock in a 3D printer, which fused the filaments together to build a series of plate-lattice designs. Those designs were then subjected to a series of impact tests — a 16.7-kg mass was dropped from a range of heights to determine the material’s ability to withstand physical shocks.

First, the team tested three types of typical plate-lattices they designed and built — a simple cube formed from the intersection of three plates, a more complex cube with additional intersecting plates, and a multifaceted design. Those typical plate-lattices were made in two batches — one from polypropylene and another from polyethylene.

Then, they tested three more “hybrid” plate-lattices that incorporated features from the simpler designs in the first experiments — a simple-cube/complex-cube hybrid, a simple-cube/multifacet hybrid, and one that amalgamated all three. Again, batches made from polypropylene and polyethylene were made.

The hybrid design, which combined elements of all three typical plate-lattice designs, proved to be the most effective in absorbing impacts, with the polypropylene version showing the greatest impact resistance. Using a measure known as specific energy absorption, which scientists use to determine a material’s ability to absorb energy relative to its mass, the team found that the polypropylene hybrid plate-lattice could withstand 19.9 joules per gram, a superior performance over similarly designed micro-architected metamaterials based on aluminum.

Dr Shanmugam Kumar, Reader in Composites and Additive Manufacturing at the James Watt School of Engineering, led the research project. The research team also involved mechanical and chemical engineers from Khalifa University in Abu Dhabi and Texas A&M University at College Station.

Kumar said: “Advances in 3D printing are making it easier and cheaper than ever to fabricate the kinds of complicated geometries with tailored porosity that underpin our plate-lattice design. Manufacture of this kind of design at industrial scale is becoming a real possibility.

“One application for this new kind of plate-lattice might be in automobile manufacture, where designers perpetually strive to build more lightweight bodies without sacrificing safety during crashes. Aluminum is used in many modern car designs, but our plate-lattice offers greater impact resistance, which could make it useful in those kinds of applications in the future.

About the Author(s)

You May Also Like