On average, plastics make up less than 10% of a vehicle’s weight yet account for approximately 50% of its volume, according to a new ACC report.

March 7, 2023

Around 2003, the average automobile weight in North America exceeded that of the previous peak in 1976. Since then, albeit with some volatility, vehicle weight has trended upward, reaching around 4,300 lb. (1,950 kg) in 2021, according to Environmental Protection Agency (EPA) data. This mass increase is despite the growing use of lightweighting plastics in vehicles and can be attributed to two trends: Passenger cars and light trucks are getting larger, and they are being crammed with more and more features. Light-duty trucks accounted for 55% of vehicle sales in the United States in 2021, up from 36% in 2012. Further, today’s vehicles are being outfitted with all manner of sensors and infotainment systems, meaning even smaller vehicles are tending to bulk up.

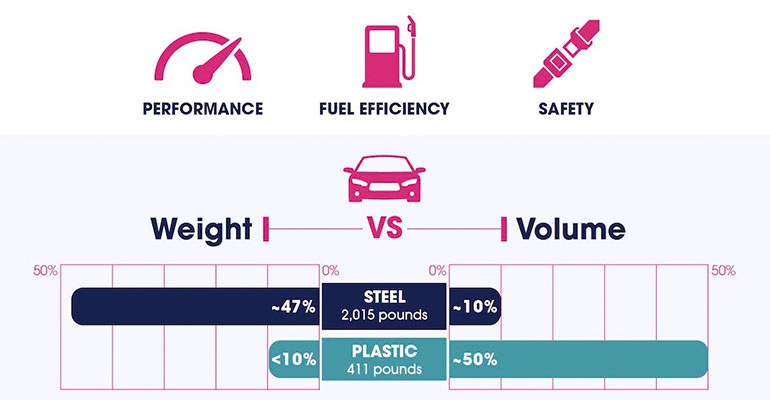

The latest report from the American Chemistry Council (ACC), “Chemistry and Automobiles,” details some interesting factoids and trends that highlight the role of plastics in automobiles. The report found that from 2012 to 2021 the average mass plastics in an automobile sold in the United States increased by 16%, to 411 lb. (186 kg). Calculations show those 411 pounds make up less than 10% of an average vehicle’s weight yet account for approximately 50% of its volume, greatly improving fuel efficiency and, in turn, reducing costs for drivers and carbon emissions from transportation.

Plastics a solid substitute for steel

The report also concludes that as electric vehicles (EVs) become more popular, plastics are more important than ever to the auto industry, not just in the vehicles themselves but also in charging infrastructure. EV batteries are significantly heavier than internal combustion engines, driving automakers to incorporate more plastic into more components of vehicles, like the chassis and battery casings, to offset that additional battery weight. Furthermore, certain high-performance plastics can absorb four times the crush energy of steel, greatly improving safety for passengers in collisions. The average vehicle in 2021 still utilized around 2000 pounds of steel and 1000 pounds of other metals and alloys, highlighting the potential for further penetration of plastics.

Innovation rooted in sustainability

“Plastics in automobiles are the ultimate example of plastics innovation rooted in sustainability. These aren’t your ordinary plastics — they must withstand high temperatures from batteries, daily exposure to UV light, and the wear and tear of a busy family,” said Joshua Baca, vice president of plastics at ACC. “What gets me really excited is how we are seeing automakers partner with our industry to not just incorporate plastics into vehicles, but to improve the recycling of those plastics at the end of a vehicle’s life.”

“This report demonstrates that the auto industry is choosing to use more plastic in vehicles and those choices are benefiting car owners, passengers’ safety, and our efforts to advance lower carbon solutions,” said Heather Rose-Glowacki, senior director of industry intelligence & analysis at ACC, and lead author of the report. “I anticipate this trend will continue to grow as EVs increase in market share.”

Adding 'chemistry value'

ACC also notes that over the past decade, the “chemistry value per vehicle” has grown by an average of 20% (or $669), which includes plastics, composites, synthetic rubber, and elastomers.

Over a dozen major resins find major usage in automobiles, according to ACC, including on average 97 lb. (44 kg) of polypropylene, 84 lb. (38 kg) of polyurethane foam, 41 lb. (18.5 kg) of polyamide, 34 pounds (15 kg) of high-density polyethylene (HDPE), and 31 lb. (14 kg) of PVC. Of these resins, HDPE’s main use is in fuel tanks, with other components using the resin including windscreen washer tanks and lubricant tanks. Accompanying the transition to EVs, HDPE usage in automobiles might be expected to decline over the medium to long term.

About the Author(s)

You May Also Like