MD Elektronik used an engineering plastic from BASF to improve data-transmission rates in its automotive cabling system while reducing size by 60% compared with a standard USB port.

February 3, 2022

The transformation of the motor vehicle continues. Alternative powertrains, autonomous driving, and the urge for more sustainability are fundamentally changing vehicle design and the driving experience.

In particular, the car interior is undergoing an extreme makeover and becoming, in essence, a mobile office and living room. Key components such as the instrument panel are transformed into entertainment units with screens for video conferencing. Such electronic devices with additional functions require ever higher data rates. This translates to demanding requirements for the high-performance equipment deployed and, thus, for the electronic components and materials used. In addition, it is necessary to reduce weight and to adopt more compact components owing to less available space.

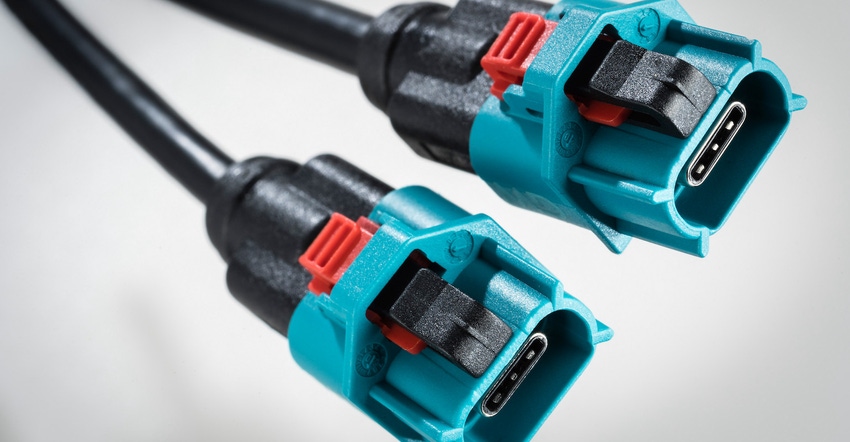

German data cable company MD Elektronik has taken on these challenges and, with the help of engineering plastics supplier BASF, developed the C-KLIC connector system conforming to the USB Type-C standard. A glass fiber–reinforced polybutylene terephthalate (PBT) suitable for use in vehicles, Ultradur B 4300 G4 requires up to 60% less space than a standard USB port because of its material properties. Moreover, the device boasts a data-transfer rate >10GB/s and optional USB power delivery.

"Our goal was to produce as many individual parts of the connector system as possible with one identical material,” explained MD Elektronik colleagues Markus Kaaserer, Expert Techno Polymers, and Johannes Trä, Director Development. "This simplifies processing, is much more efficient, and contributes to sustainability by reducing material changes on the production machines. Thanks to BASF's extensive product portfolio, we had several solutions to choose from."

Due to the material properties, Ultradur is used in the connect+adapter (CPA) element, coding housing, and internal overmolding. The PBT grade displays its full strength especially in the internal component. Further, thanks to its electrical properties and dimensional stability, the engineering plastic protects the sensitive electronics from external influences such as humidity and dirt. Compared to a standard USB charging module with integrated electronics, the new connector system can be produced in much smaller dimensions, which saves installation space and weight.

"This new development underscores the shift toward infotainment in the car interior," said Bernd Skupin, Global Key Account Manager at BASF's Performance Materials division. "The connector system enables much greater data transmission than systems used in current cars. With the ever-increasing demand for high-performance electronic devices in vehicles, we can use our expertise to provide excellent support for new developments."

The Ultradur grade fulfills another important requirement, according to Volker Zeiher, Senior Specialist, Technical Development, at BASF. “Due to the very good dimensional stability and low humidity absorption, tight tolerances can be maintained regardless of the ambient conditions in the vehicle." Consequently, the automotive-compatible connector design represents an ideal solution for future vehicle concepts, which is another step toward a living room on wheels.

About the Author(s)

You May Also Like