Development of a composite with a polyamide 6 matrix containing more than 80% of sustainable raw materials is almost completed.

July 6, 2022

Lanxess is placing an emphasis on sustainability in its business activities, and new Tepex thermoplastic composites currently being developed based on recycled or bio-based raw materials are the latest example. “With these construction materials, we want to help our customers to make more sustainable products that have a smaller carbon footprint, conserve resources, and protect the climate,” explains Dr. Dirk Bonefeld, Head of Global Product Management and Marketing for Tepex at Lanxess. Recently, the specialty chemicals company launched a fully bio-based composite material based on flax and polylactic acid.

Development is about to be completed, for example, on a matrix plastic based on polyamide 6 for Tepex dynalite that is produced starting from “green” cyclohexane and comprises more than 80% of sustainable raw materials. The plastic meets the requirements that Lanxess has set for its new Scopeblue range — products that contain a significant proportion of circular (recycled or bio-based) raw materials or have a considerably smaller carbon footprint than their counterparts.

When the matrix plastic is reinforced with continuous-fiber fabrics, the resulting semi-finished products exhibit the same properties as comparable, equivalent fossil-fuel-based products. The semi-finished products with a green matrix are suitable for applications in structural lightweight designs that are typical for Tepex dynalite, such as front-end carriers, seat shells, or battery consoles.

Bundling high-class décor and high-grade mechanical properties

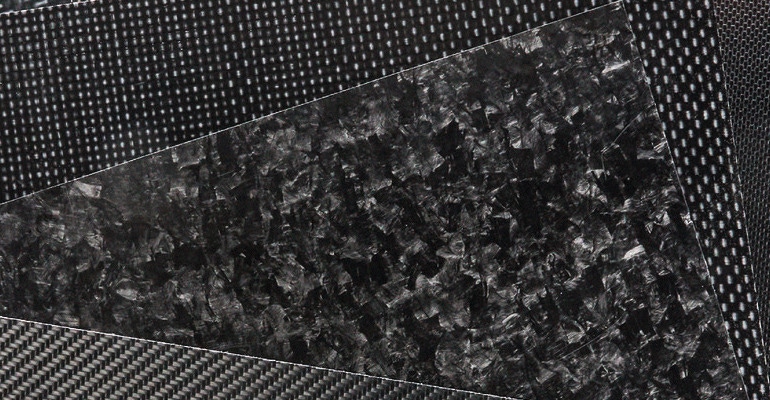

Another new product line comprises variants of Tepex with up to 80% recycled material that yield surfaces with a so-called forged carbon look. The corresponding components feature a grain that is reminiscent of marble. The high proportion of recycled material is based on carbon fibers from post-consumer and post-industrial waste. The fibers are used as non-woven material or chopped fiber mats. A variety of thermoplastics are suitable as a matrix material, such as polyamide 6 and 66, polypropylene, or polycarbonate, whereby types of recycled material made up of these plastics can also be used.

The fibers in the composite semi-finished product have no preferred orientation, meaning that the mechanical properties of the resulting components are isotropic (the same in all directions). The mechanical performance of the new carbon composites approximates the high level of the continuous-glass-fiber reinforced composites of the Tepex range. “We see good opportunities for these products in applications that at once require high-class decor and high-grade mechanical properties, such as in car interiors and exteriors or in housings for consumer electronics,” says Bonefeld.

Bio-based alternatives to polyamide 12

Another development focus is new matrix solutions for Tepex based on recycled thermoplastic polyurethane (TPU) or polyethylene terephthalate (PET) as well as on bio-based polyamide 10.10. The recycled TPU products are primarily intended for sports equipment.

One of their strengths is the good composite adhesion with many other injection-molded materials when processed using insert molding or hybrid molding methods. The semi-finished products with a PET recyclate matrix are a cost-effective alternative to virgin polycarbonate and polyamide, for example. The PET is derived from post-consumer beverage bottles and is also available in large quantities thanks to the closed recycling chain for these bottles. The bio-based polyamide 10.10 is derived from castor oil. “The composite materials made with it are a sustainable alternative to polyamide 12 composites, because they have similar mechanical characteristics and a comparable density,” says Bonefeld.

Lanxess will showcase these and other developments at K 2022 in Düsseldorf, Germany, on Oct. 19 to 26, 2022. The company will exhibit in booth C 76-78 in hall 6.

You May Also Like