Automotive design engineers have achieved lightweighting success with polypropylene for decades, but large interior panels present ongoing challenges. A new PP impact copolymer from ExxonMobil with greater ductility, high flow, and scratch resistance presents a solution.

January 11, 2023

Sponsored by ExxonMobil Company

Brian Dujardin

Lightweighting is an ongoing need in the automotive industry, and plastics continue to play a key role for innovations in internal combustion engine (ICE) vehicles as well as electric vehicles (EVs). Whether the goal is to improve ICE fuel economy or to extend EV range, reduction of vehicle weight is a key enabler.

Plastics, therefore, remain front and center in the search for new and better lightweighting solutions. Today, plastics represent about 50 percent of the volume of a vehicle but only account for 10 percent of total weight, according to the American Chemistry Council. Even after decades of innovation however, there remain new challenges and new frontiers to cross. Polypropylene (PP) resins, whether used in compounds or “neat” (i.e. no fillers added), provide a prime example of these new solutions and frontiers.

This article will focus on new innovations that will continue to transform the interior of the car.

Impact copolymers, always evolving

Designers have been searching for ways to reduce the weight of a vehicle without sacrificing performance. The interior of a car is the perfect place to look at providing weight savings, with so many parts produced from PP: instrument panels, door panels, pillars, quarter trim panels and lift gates.

PP impact copolymers (ICPs) are widely used for many of these applications due to the need for excellent impact resistance. The question has been though: “Should I select a compounded or a neat ICP for my part design?”

Factors such as material performance, manufacturing/machinability, look-and-feel of the part, cost, and more all must be balanced to select the right material. Even though neat PP, as the lowest density option, provides the greatest weight savings, it hasn’t always been able to meet the demands of these more challenging applications. This has led designers to select compounded PP materials, typically with talc, which increases the density and therefore the weight of the part.

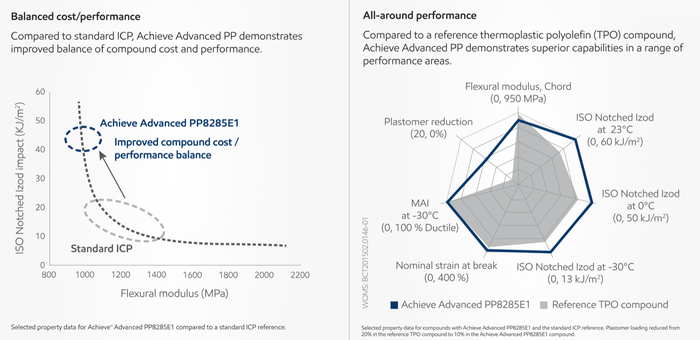

This is changing with the development of an ICP with greater ductility and an excellent balance of properties. Achieve™ Advanced PP8285E1 is enabling automakers to use neat ICPs in the interior of the car and take advantage of the lowest density materials in the market. This material was originally developed for use in PP compounds, but it is now finding opportunities in neat applications as automakers continue their push for weight savings.

Automakers take the ‘door panel’ challenge

Achieve Advanced PP8285E1 holds promise for automakers and their Tier 1 partners who have searched for a suitable PP to broaden usage in interior trim and door panel applications. It enables automakers to take advantage of weight-saving opportunities and addresses challenges, such as ductility.

This new advanced ICP can help engineers design large, lighter-weight panels that perform well, and in a cost-effective manner versus compounded PP. Features include:

Lower density (0.90 versus a typical density of 0.98 for compounded PP) and therefore lower weight relative to compounds found in automotive interiors

Higher ductility versus standard ICPs, which allows the door panel and interior trim parts to pass airbag deployment and other real-world impact testing performed by automakers

Enhanced molding due to a higher melt index of thirty (i.e., melt-flow rate flow rate of 30 g/10 min) vs. the industry standard of twenty - this allows lower pressures, reducing injection molding machine tonnage requirements, and can reduce parting line flash for higher finished product quality

Improved scuff and mar resistance over current alternative ICP’s

Proof of performance has been tested as follows:

Consider how these attributes may finally open new applications for door panel lightweighting. Switching from a compounded PP for a 4-pound door panel on a sedan to this ICP would total around 1.5 pounds of weight savings per vehicle. That weight reduction becomes 150,000 pounds per 100,000 vehicles.

Using this same approach, many applications in the interior of the vehicle besides door panels can use neat ICP instead of compounded PP. This volume has been estimated at 65 pounds per vehicle based on a recent vehicle launch in North America. Using Achieve Advanced PP8285E1 instead of a compounded PP is saving the automaker approximately 5.5 pounds per vehicle.

The US auto industry sold nearly 15 million cars and light trucks in 2020, according to Statistica. Imagine the improved vehicle efficiency if neat ICPs were used in all viable interior trim applications.

Taking the advanced ICP challenge

The history of automakers’ efforts to use neat ICPs for lightweighting large and complex parts has historically had mixed success. Some early efforts were abandoned in favor of compounded PP, while others returned to the material for value-oriented vehicles. Today, automakers are scattered across both camps. However, this new ICP has made an enormous difference in the industry and more door panels are indeed rolling off production lines using this higher performing material.

You can download data sheets (like this one) but beware, test methods vary from vendor to vendor. It is not straightforward to conduct a true “apples to apples” comparison, particularly for cold-temperature impact testing. Therefore, a real-world test is where the proverbial rubber meets the road: Get pellets into the hands of suppliers and molders, and have them produce test parts to see how well the material performs.

Until then, click to view a video case study on Achieve Advanced PP8285E1. A large, global manufacturer highlighted the benefits of this new ICP including quality, consistency, overall performance, and reduced molding cycle times. The manufacturer also mentioned reducing weight and increasing impact resistance at low temperatures when using this material.

About the Author

Brian Dujardin, Customer Application Development with ExxonMobil Product Solutions Company, has been with the company for 23 years. His experience includes OEM and supplier support, problem-solving, and process optimization; assembling multi-lot certifications for polypropylene and polyethylene materials; and injection molding prototyping, mold making, and production.

You May Also Like