Materials suppliers are responding to mandated standards and automakers’ voluntary efforts to improve air quality in vehicles.

November 15, 2017

Japan’s Polyplastics says it now offers the industry’s most extensive range of polyoxymethylene (POM) resin grades with low-VOC emissions for the production of automotive interiors. The company’s Duracon low-VOC acetal grades are specifically designed to meet the latest regulations governing the concentration of VOCs in automotive interiors.

Polyplastics’ low-VOC grades enable its customers to produce molded parts that conform to today’s regulatory requirements for automotive interiors. These materials also contribute to an improved plant environment thanks to a reduction in the quantity of VOC emissions at the molding site, as well as a reduction in mold deposits which cuts the frequency of mold maintenance. The company utilizes technology which reduces the quantity of residual formaldehyde within resin pellets through the use of optimal stabilizers and scavengers.

Polyplastics’ low-VOC line includes Duracon M90-45LV — an improved weather-resistant grade. It exhibits an extremely low quantity of released formaldehyde compared to competitive grades. Duracon M90-45LV features improved weather resistance which delays the deterioration caused by ultraviolet light and the corresponding degradation of physical properties.

Another low-VOC grade is NW-02LV, a high-sliding material which provides excellent friction and abrasion characteristics and low-sliding noise. Other low-VOC resins include a glass-reinforced grade (GH-25LV), a low-gloss offering (LU-02LV), and an impact-resistant grade (TF-10LV). Duracon TR-20LV is a high-rigidity/low-warpage grade while Duracon M270LV is a high-flow material.

Duracon low-VOC grades are also targeted at non-automotive applications such as office automation equipment. The downsizing of PCs, photocopying machines, and projectors has led to rising internal temperatures, creating potential for the release of larger quantities of VOCs.

|

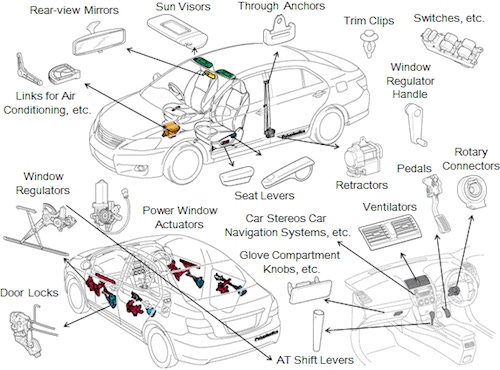

Polyacetal finds wide usage in many applications that potentially expose vehicle occupants to VOCs |

About the Author(s)

You May Also Like