The race car maker collaborates with Bcomp to develop F1's first natural fiber composite racing seat.

September 11, 2020

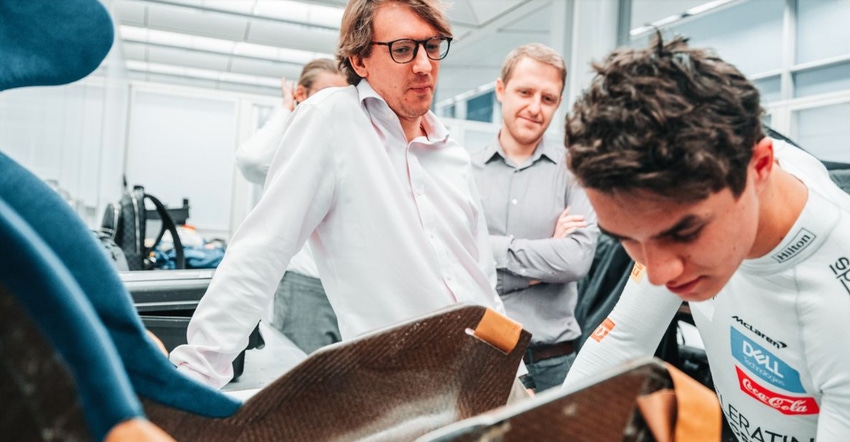

Formula One race car manufacturer McLaren been working with Swiss sustainable lightweighting specialist Bcomp to develop natural fiber-reinforced racing seats for its drivers Carlos Sainz and Lando Norris – the very first F1 car part to be made of renewable textile fibers. By optimizing the mechanical properties of flax fibers through fabric architecture, the seat can be fabricated with the required strength and stiffness, but with a 75% lower CO2 footprint compared to its carbon fiber counterpart.

“The use of natural fiber composites is the latest example of pioneering, composite materials innovation at McLaren,” explains McLaren F1 Team Principal Andreas Seidl. “Not only does this solution provide equivalent performance to carbon fiber, it represents another step forward in our evolving sustainability programme, while underlining our commitment to helping F1 turn its ambitious sustainability strategy into action.”

Primarily used in the production of linen, flax is an incredibly versatile plant that has been around for millions of years. It differs from many biomaterials in that it’s ideal for use in crop rotation programs and can be grown without directly competing with food crops. Flax is a CO2-neutral raw material and its fibers are biodegradable. At the end of the seat’s life, for example, it can be ground down into a new base material or thermally recycled without residual waste, rather than end up in landfill.

|

Flax fiber-based composites employed in F1 seat boast greater vibration absorption and impact resistance than carbon fiber. Image: McLaren. |

Inspired by the thin veins on the back of leaves, Bcomp’s proprietary powerRibs technology provides a three-dimensional grid structure on one side of the seat, which is then used to reinforce Bcomp’s optimally spun and woven flax fiber reinforcement fabric, ampliTex. Made by twisting flax fibers to form a thick yarn, the powerRibs act as a backbone to the ampliTex flax fabric that is bonded to it.

Since 2019, a minimum driver weight of 80 kg has been mandated. And if a driver weighs less than that, ballast must be used to bring them up to the minimum weight. But instead of allowing this ballast to be placed in other areas of the car, which could improve weight distribution, it must be located within the immediate area of the driver’s seat.

“With the introduction of the new regulation in 2019, the seat now forms part of the driver’s weight budget, so it’s over-engineered as a result,” explains McLaren F1 Principal Composites Engineer Steve Foster. “And with Carlos and Lando weighing in at 72 kg and 68 kg respectively, there’s plenty of scope to do that. It meant that, if we needed to, there was margin to use additional bio-composite material to ensure sufficient strength and stiffness in this safety-critical component.

“The original carbon fiber seat design was reverse-engineered by Bcomp, and then we optimized and manufactured the new design. The seat was run in pre-season testing without any problems and we hope to be racing with Bcomp flax seats in the near future.”

“We believe this seat functions as a conclusive demonstration that our technologies are ready to compete in the top tier of motorsport,” adds Bcomp CEO and Co-Founder Christian Fischer. “We match conventional carbon fiber while lowering the eco footprint by 75%, cutting costs, reducing vibrations and improving safety – all of which are highly relevant to achieving a sustainable future for motorsport and mobility.”

While the environmental benefits are clear, the mechanical properties of flax make it an attractive renewable raw material for high-performance composites. The tubular structure of flax fibers provides low density and high stiffness, which affords the opportunity to reduce weight while simultaneously improving vibration damping, as well as resistance to breakage, torsion and compression.

Flax fibers are also 9% lighter than any equivalent carbon material and offer five-times better vibration damping. Greater vibration absorption and impact resistance makes the natural fiber material well suited to use in the driver’s seat. It improves comfort and reduces vibration in the cockpit, which can have a fatiguing effect on drivers, especially over a race distance and particularly at circuits with aggressive curbs.

When it does break, unlike carbon fiber, it’s not prone to brittle fracture and splintering – a property that’s enhanced further by the structure of Bcomp’s powerRibs which stiffen and confine the damage zone. “The composite of ampliTex and powerRibs is not as fragile, and while it still breaks, the softer debris remains attached to the main structure with the help of the powerRibs, which help dissipate the energy,” explains Fischer.

The ductile fracture behavior of natural fiber composites opens the door to other possibilities too. One of the most spectacular, but equally dangerous, aspects of an on-track incident are the shards of carbon fiber that result from a collision. Not only do they present an immediate risk to the drivers, they are notorious for causing punctures and leaving a driver’s race in tatters. By using natural fiber composites in other areas of the car, such as front wing endplates and the floor, it’s possible to reduce carbon fiber debris and therefore the risk of punctures.

The advantages don’t stop there. With a budget cap set be introduced from 2021, many F1 teams will need to reduce costs while maintaining and improving performance – no mean feat in a sport where, typically, a team can pursue more development routes the more resource it has available. Teams are going to have to work even smarter, and with Bcomp’s ampliTex and powerRibs solutions reducing raw material cost by up to 30% compared to traditional carbon fiber, this significant saving can free up budget to explore other ways of improving car performance.

“With the introduction of the budget cap, the cost of materials is going to be a big focus and the use of natural fiber composites has the potential to help in this area,” acknowledges F1 Technical Director James Key. “We’re working with Bcomp to confirm that natural fiber composites are a viable, sustainable and economical substitute for carbon fiber in some applications, both on and off the car.

“Where we see significant potential is in the non-critical, semi-structural areas of the car, such as the driver’s seat, as well as off the car,” says Fischer. And it’s the latter, reveals McLaren F1 Principal Composites Engineer Steve Foster, where the immediate scope for further adoption of natural fiber composites really lies: “When used intelligently, the flax fibers reduce weight and cost, while maintaining and, in some cases, even improving performance. There are a range of possible applications beyond the car itself, including pit gear, truck panels, packing cases, timing stands and mold tools.”

Currently, most of the molds used to make parts of the car, are made of carbon fiber composite because it has low thermal expansion. However, flax fibers also possess this property, potentially making them a suitable tooling material for moulding performance parts that are made from standard composites. So even if the part being produced isn’t made from natural fiber materials, the tool to produce it can be – allowing us to reduce the cost of mold tools and our carbon footprint.

About the Author(s)

You May Also Like