Glass fiber-reinforced grade also achieves higher gloss for mirror surfaces and lower gloss for grained surfaces.

April 13, 2017

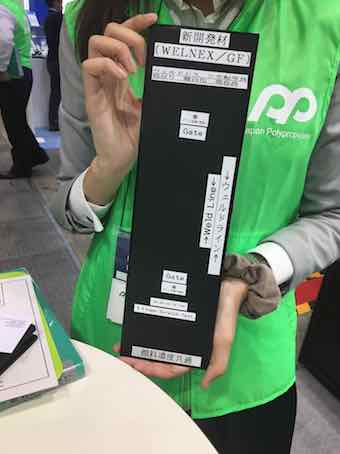

Weld line elimination and excellent surface appearance are key properties achievable with a new grade of glass fiber-reinforced thermoplastic polyolefin (TPO) based on metallocene catalyst and process technology developed by Japan Polypropylene (JPP, Tokyo). The primary target application of Welnex/GF is automotive interior components.

|

Welnex/GF delivers weldless injection-molded parts. |

As opposed to conventional talc-filled polypropylene (PP) grades employed in interior applications, weld lines are almost invisible with the new grade, which crystallizes relatively slowly like a random copolymer grade, resulting in better integration of the two flow fronts. According to a JPP spokesperson, while the cycle time might consequently be roughly 10% slower, advantages such as no need for coating and a softer feel despite the 10–30% glass fiber reinforcement content have already convinced some end user to adopt the material.

Further advantages of Welnex/GF include excellent mold pattern duplication, i.e., higher gloss for mirror surfaces and lower gloss for grained surfaces. And remarkably, according to JPP, glass fibers are invisible in grained surfaces.

The grade is also said to exhibit outstanding color vividness (good pigment dispersion), anti-stress whitening, and less shrinkage and warp, meaning larger parts can be molded. A Welnex/GF 20% glass fiber-reinforced grade exhibits an MFR of 30, flexural modulus of 2730 MPa, Charpy impact strength at 23°C of 30 kJ/m2, and shrinkage in the flow direction of 1.2x10-3.

JPP has also reported developmental progress in its Waymax metallocene-catalyzed high melt strength PP material. Using double-sided vacuum forming machinery commonly used to process polystyrene foam sheet, 4.2-mm thick extruded foamed sheet (10-fold expansion ratio) is now possible.

JPP is also touting Waymax as a film modifier for air-cooled blown film processed using its Wintec metallocene random copolymer PP resin. Addition of 10% of Waymax grade MX3 to the core Wintec layer achieves better bubble stability, and hence higher productivity, with no sacrifice in haze, which is maintained at a level of 2.6%.

About the Author(s)

You May Also Like