Composites Evolution has introduced a range of flax-reinforced epoxy prepregs to meet demand from the motorsport sector

December 9, 2019

Composites Evolution has introduced a range of flax-reinforced epoxy prepregs to meet demand from the motorsport sector. To reduce environmental impact, there is increasing interest across several motorsport series in the use of natural fiber composites for parts such as aerodynamic devices and doors. The GT4 class of racing machines has been leading the way with recent models from the likes of Porsche and Toyota featuring natural-fiber body parts.

|

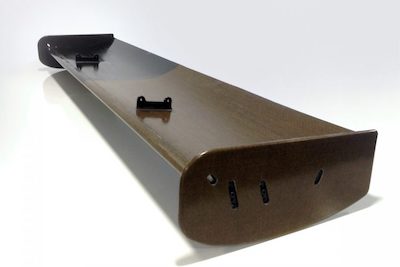

Composites Evolution has introduced a range of flax-reinforced epoxy prepregs to meet demand from the motorsport sector [Photo courtesy of KW Special Projects Ltd.] |

Composites Evolution has brought together its extensive expertise in high-performance flax reinforcements with its Evopreg range of epoxy prepregs to offer motorsport customers a proven and flexible range of material and design options. The new flax-epoxy prepreg products include a lightweight woven surface ply (100 g/m², 2×2 twill), a medium weight woven ply (300 g/m², 2×2 twill) and a 150 g/m² unidirectional ply. Other prepregs, including biaxials and in fabric weights of up to 700 g/m², are available on request.

Composites Evolution’s technical support team is available to assist customers in introducing flax-reinforced composites into their designs. They can offer advice on getting the best out of flax-reinforced Evopreg materials, including aspects such as cutting, lay-up, curing and on-track durability.

Using materials supplied by Composites Evolution, KW Special Projects has applied their expertise in component manufacturing to produce a GT rear wing component. To demonstrate the use of flax prepregs alongside other high-performance materials, half the wing has been produced in flax-epoxy and half in carbon-epoxy.

Brendon Weager, Composites Evolution’s Technical Director, commented “No other prepreg supplier has the depth of flax knowledge that resides within Composites Evolution. We’re ideally positioned to help motorsport customers introduce natural fiber materials into their cars and bikes.”

About the Author(s)

You May Also Like