Duranex 532AR exhibits enhanced toughness and resistance to alkali substances.

January 18, 2019

Japan’s Polyplastics has introduced of a new polybutylene terephthalate (PBT) resin which reportedly delivers excellent alkali stress crack resistance for a range of automotive applications. The new grade, Duranex 532AR, also exhibits outstanding hydrolysis and heat shock resistance, as well as electrical performance for components in the chassis and engine compartment.

|

Duranex 532AR exhibits enhanced toughness and resistance to alkali substances. |

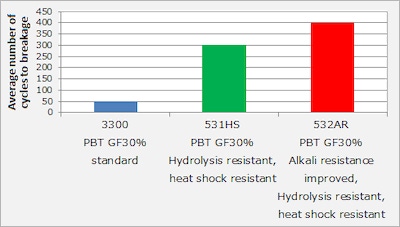

As the demand for durability, safety, and reliability in auto parts continues to increase, Duranex 532AR reduces the risk of cracking in molded parts by preventing alkali from penetrating the inside of the resin, thus imparting toughness that helps generate less stress. Alkaline substances can arise from rust formation in metal parts. Duranex 532AR is treated with a hydrolysis-resistant formula and has greater durability than standard materials.

Recent test evaluations show that when specimens are immersed in alkali, cracking occurs within two hours in standard material Duranex 3300 and in hydrolysis- and heat shock-resistant Duranex 531HS. However, no stress cracking occurs in Duranex 532AR even when immersed for up to 200 hours.

Electrical components and sensors installed near the engine are often metal insert molded and there are cases when sudden temperature changes can cause heat shock fracture. This occurs because the metal and resin have linear expansion coefficients that differ by roughly a factor of 10. Duranex 532AR has outstanding heat shock resistance and is capable of withstanding these harsh environments.

Duranex 532AR is reportedly ideal for use in parts installed in the chassis and areas of vehicles which can be exposed to water and mud splashes, and come into contact with chemicals such as snow melting agents. The new grade offers a combination of high reliability and long life even in harsh environments.

About the Author(s)

You May Also Like