The material’s balance of dimensional stability, strength, and other performance characteristics as well as its processability make it suitable for the production of automotive, electrical, and electronic parts.

July 13, 2021

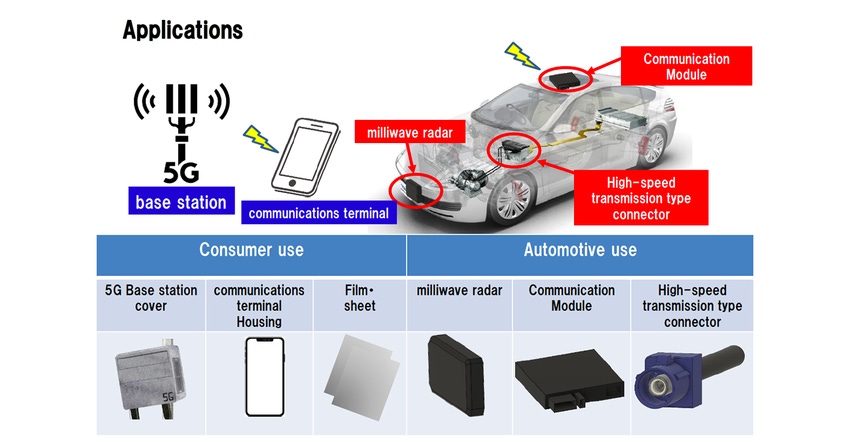

Japan’s Toray Industries has developed a high-performance polybutylene terephthalate (PBT) with 40% lower dielectric losses in the high-frequency millimeter wave band than conventional PBT without compromising dimensional stability or moldability. The material will significantly enhance the performance of high-speed transmission connectors, communication modules, millimeter wave radars, and other equipment for 5G base stations and automated driving systems, said Toray. The material’s balance of dimensional stability, strength, and other performance characteristics as well as its processability open up numerous applications in the production of automotive, electrical, and electronic parts.

Growing demand for reduced dielectric losses in high-frequency components for automated driving systems and other applications has led to the adoption of polymer alloys and fillers, noted Toray. However, the potential reduction in dielectric losses is compromised by these resins, which are also plagued with heat resistance issues and mechanical property degradation.

Toray said that its PBT delivers a loss tangent of 0.006 in the ultra-wide 79-GHz millimeter wave band. Losses from that factor are around 40% below conventional PBT resins while retaining their basic properties. This was achieved by constraining the polymer’s molecular motion in the high-frequency range through a polymerization technology.

The dielectric loss is low across 5G communication frequency bands, from sub-6 GHz to high-frequency millimeter wave bands, and dielectric stability is ensured in hot and humid environments. The new PBT cuts transmission losses and enables wide-area sensing, which can be an issue when designing high-frequency components, said Toray.

It has been challenging to downsize products without changing the resistance of electric circuits and connectors.The low dielectric loss of this new resin makes it possible to keep electrical resistance unchanged, which should contribute to shrinking products, reducing weight, and improving performance, according to Toray.

About the Author(s)

You May Also Like