The Radilon Mixloy materials from RadiciGroup High Performance Polymers have multiple automotive applications, including interiors and engine parts.

July 22, 2020

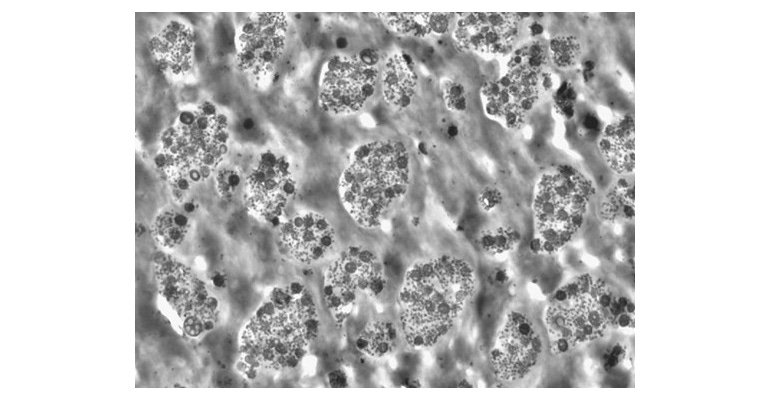

To maximize polymer performance, Italy’s RadiciGroup High Performance Polymers has introduced a specialty range of polyamides (PAs). The Radilon Mixloy products are made by blending readily available polymers via a compatibilization technology that makes naturally immiscible raw materials miscible.

“At the moment, development is focused on certain types of alloys,” noted Nicolangelo Peduto, R&D Manager. “But in the future we plan to add other products with the goal of achieving properties that are simply not attainable with individual polymers. One of our objectives is to be able to meet demand coming from niche markets. Furthermore, thanks to our upstream vertically integrated polyamide products, we have at our disposal a number of different types of polymers that give us design freedom in formulating the new Radilon Mixloys.”

The base materials for the Radilon Mixloy product range developed so far are PA 6, PA 6.6 and long-chain PAs, some of which are made from bio-sourced materials, thus increasing the value of the products, said RadiciGroup.

Properties of the new Radilon Mixloy range include thermal and mechanical resistance along with surface appearance. The materials also feature low density, dimensional stability, and processability, stated RadiciGroup. Other promising advantages of these blends are low water absorption, improved tribological properties, and low permeability.

Applications include automotive interiors, where the most frequently requested characteristics are appearance and chemical and thermal resistance, as well as exterior body and engine compartment parts. In the consumer and industrial goods markets, the new blends can be used in sporting goods, household appliances, and electronic equipment housings.

About the Author(s)

You May Also Like