Targets two-component automotive window trim and sealing applications

October 20, 2017

At this year’s Fakuma in Friedrichshafen, Kraiburg TPE debuted a new series of thermoplastic elastomers especially developed for excellent adhesion and UV resistance in two-component applications with ethylene propylene diene monomer rubber (EPDM). The new Thermolast K compounds are intended primarily for automotive applications such as EPDM window trim and sealing profiles with molded TPE corner joints and end elements.

The automotive industry is the largest and fastest-growing market for thermoplastic elastomers (TPE). New applications exist for door and window seals, which require dimensionally stable corner joints and end elements. This has been achieved in the past with styrene-butadiene compounds (SBC) and crosslinked thermoplastic vulcanized (TPV) rubber. The cost-effectiveness of TPV is limited, however, due to diverse factors in the manufacturing process, in particular the window trim. The EPDM adhesion series from Kraiburg TPE offers a good alternative with added value.

|

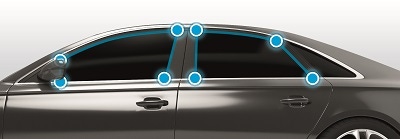

Window trim and sealing profiles made of EPDM with molded Thermolast K corner joints and end elements. (Photo: © 2017 Kraiburg TPE) |

|

The new TPE series combines excellent weather resistance and adhesion to extruded and foamed EPDM profiles. (Photo: © 2017 Kraiburg TPE) |

“The production of diverse sealing frames and window trims consisting of EPDM profiles with molded corner and end elements requires new material solutions,” says Michael Pollmann of Kraiburg TPE. “The versatility of our TPE technology has made it possible for us to develop a competitive material that solves the phase separation problems of the systems that are currently used. In addition, we have the market expertise and customer orientation for fast implementation of such innovative two-component applications.”

The core requirements for corner joints and end elements of window trim profiles include excellent adhesion and weathering resistance, which are ensured by the long-term process stability of the TPE/rubber connection. It is also necessary to minimize the injection temperature of the TPE solutions in order to reduce the cooling and cycle times of the 2-component elements.

The AD/EPDM/UV series fulfils all of these requirements by combining optimal adhesion properties with long-term resistance to UV radiation and thermal effects with a hardness of 70 Shore A. Compared to competitive materials, these special TPE products exhibit superior stability. The EPDM profile is neither compressed, nor destroyed or deformed. The compounds feature uniform color fastness versus EPDM and there is no tendency of stickiness or phase separation.

Kraiburg TPE has examined the suitability of the new materials in comprehensive adhesion, weather exposure and thermal ageing tests. The processing properties and stability were optimized in close cooperation with the machine and mold manufacturers. “Our tests showed that the cleanliness of the EPDM contact surfaces with the TPE are crucial in these two-component elements and that freshly cut seal profiles result in optimal adhesion.”

The AD/EPDM/UV technology is already being tested by several customers in the automotive industry.

About the Author(s)

You May Also Like