Drop-in replacement using original tooling; cost-effective component solution with weight saving; strict requirements regarding dimensional tolerance fulfilled.

October 7, 2019

Polyamide (PA) 6 and 66 are very similar in terms of their characteristics. PA 66 can therefore be replaced by PA 6 in many applications. One example of this is a steering column switch housing used in various models of the Ford Fiesta, Ford Focus and Ford Eco Plus.

|

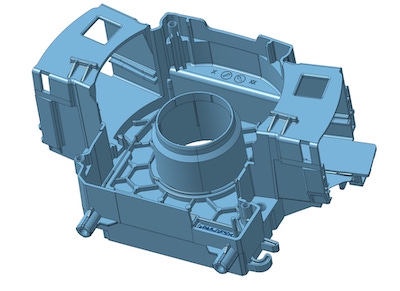

Steering column switch housing is molded from foamed PA 6. |

The component is produced by Leopold Kostal GmbH & Co. KG. Based in Lüdenscheid, German, this family-owned company is one of the world's leading system suppliers and developers of control elements, sensors and control units. It initially used a glass-fiber-reinforced PA 66 for the housing, and recently switched over to Durethan BKV30H3.0, a PA 6 compound from Lanxess featuring 30 percent by weight glass-fiber reinforcement.

“The change of material took place directly in the standard tool originally developed for PA 66. No changes were necessary. Our material had the edge because it enables a cost-effective component solution and also meets the strict requirements regarding dimensional accuracy,” declared Bernhard Helbich, an expert in technical marketing at the High Performance Materials (HPM) business unit at Lanxess.

The housing is injection molded from foamed PA 6. This foaming process has several advantages. In comparison with solid components, it saves material and weight – with reasonable compromises in terms of mechanical characteristics. “The use of foam injection molding with our material results in a weight reduction of close to 10 percent,” said Helbich. In addition, foaming leads to a considerable reduction in warpage and shrinkage in particular. This is good for the dimensional accuracy of the component, which accommodates numerous steering wheel functions such as switches for the turn signals and the windshield wipers, and thus features a highly complex geometry.

According to Helbich: “The high dimensional accuracy ensures that the switches work reliably throughout the car’s entire life and can be operated smoothly.” A further benefit of the foaming process is the discernibly lower cavity pressures. The component can therefore be produced on smaller injection molding machines with lower clamping forces. Compared with solid molded parts, this also leads to shorter cycle times, which ultimately paves the way for cost advantages.

HPM supported Kostal in switching over materials as part of its HiAnt customer service. The services included comprehensive advice in selecting the material and the production process. In addition, processing experts from Lanxess helped to optimize the series process.

About the Author(s)

You May Also Like