Grade meets demanding requirements of sensors for automated driving.

December 8, 2020

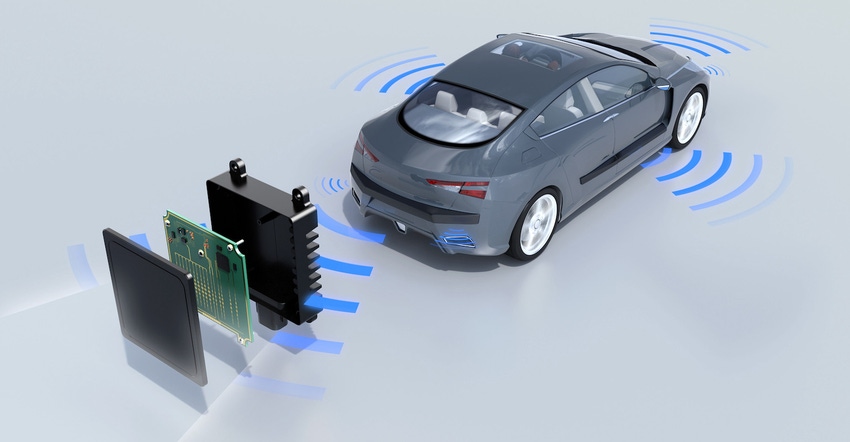

The development of new technologies for the automotive industry focuses on comfort and the safety of passengers. Chemistry has already made a decisive contribution to this and will also play an important role in future mobility challenges. In addition to electromobility, automated driving is a crucial building block for the mobility of tomorrow. Closely linked to this development is the increased use of sensors.

With Ultradur RX, BASF has now developed a modified polybutylene terephthalate (PBT) specifically for radar sensor applications in vehicles. Thanks to its good resistance against media such as splash water, oils, or salt, Ultradur PBT offers exceptional protection for sensor housings. In addition, the new material shields the sensitive electronics in the housings against disturbing electromagnetic waves from other vehicles.

"The different grades of the new Ultradur RX series are products designed for absorption and reduction of interference radiation in the range of 76 to 81 GHz. They offer a high level of protection of the sensitive electronics," explains Dr. Erik Gubbels, R&D Ultradur expert in the Performance Materials division at BASF. "This dielectrically optimized material fulfills the high standards for sensor components and is suitable for the use as a rear housing cover or behind the printed circuit board of a radar sensor, for example."

With increasing electromagnetic interference issues in road traffic, it is crucial that for optimal sensor functioning this noise is absorbed and, therefore, reduced. By suppressing disturbing radar radiation, a better assignment of the received signals is possible, which at the same time means an improvement in safety. As a functionalized plastic, Ultradur RX is a good alternative to metal housings, contributing to weight savings and higher vehicle efficiency.

Since the absorption properties depend on geometric conditions, a suitable material must be selected for each application — the new Ultradur RX portfolio offers solutions for any circumstance and is now commercially available.

About the Author(s)

You May Also Like