The use of high-flow PBT reduces weight by 60% compared with metal-based structures while achieving dimensional stability, low warpage at short cycle times, and temperature resistance.

September 6, 2021

Car buyers tend to put panoramic roofs at the top of their list of extras when buying a new vehicle. This trend co-exists with the need to reduce the weight of all automotive components.

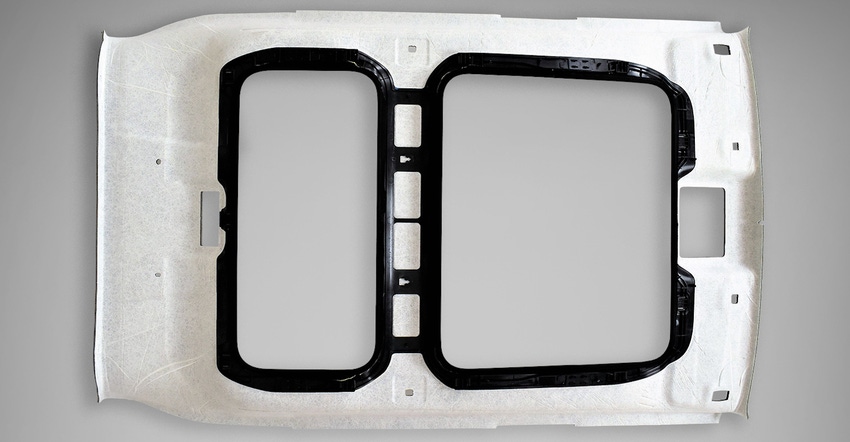

BASF and Grupo Antolin are rising to this challenge with the development of interior parts molded from engineering plastics. A new panorama roof integrated into the ceiling trim (headliner) is but one example. Made of lightweight Elastoflex E 3943/134 polyurethane, the sunroof opening in the headliner is supported by a structural bracket. Traditionally this is made of steel. Replacing the metal with Ultradur High Speed polybutylene terephthalate (PBT) provides the needed dimensional stability and mechanical properties.

In close cooperation, both companies have successfully validated the Ultradur High Speed PBT in plastic frames for open panorama headliners. The novel design of these parts allows a weight reduction up to 60% compared with traditional solutions. The material allows injection molding of large parts, achieving excellent dimensional stability, low warpage at short cycle times, high stiffness, high temperature resistance, and outstanding flowability, according to the companies.

“One of the main advantages of the newly designed plastic parts is the change in the process,” explained Enrique Fernandez from Grupo Antolin. “We attach the frame to the headliner. During the production process, the panorama reinforcement frame is fixed to the interior trim part while the part is formed in the mold. That leads to the elimination of additional process steps. Moreover, it improves tolerances during assembly and the quality of the final part. The new process does not involve the use of any solvents [and does not] generate hazardous emissions,” added Fernandez.

“The new rheological modified Ultradur High Speed has outstanding flowability that is crucial to obtain large and slim interior trim parts. Moreover, considering its unprecedented processing advantages, we have been able to reduce weight without losing stiffness and dimensional stability at high temperatures,” said Dirk Salzmann of the Performance Materials division at BASF.

Following pre-development with a German customer, the first pilot project was launched for a best-seller vehicle. More opportunities with this solution have been identified for several OEMs at global scale.

About the Author(s)

You May Also Like