The carbon-fiber prepreg cures in 60 seconds.

June 1, 2021

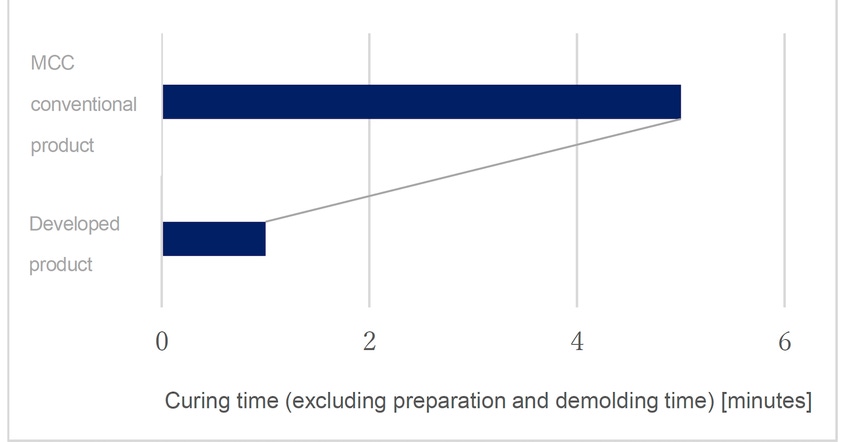

Mitsubishi Chemical Corp. (MCC) has announced availability of a carbon-fiber prepreg that can be cured in 60 seconds, substantially faster than conventional products.

Suited for use in mobility applications, where there is growing demand for lighter weight aircraft and automobile bodies, carbon-fiber reinforced plastics (CFRPs) also show promise in the wearable device market, according to MCC.

Typically, it takes a fair amount of time to mold and fabricate CFRPs, said MCC, and the long cycle times have limited potential applications. This technology improves productivity, opening up new opportunities for the use of CFRP.

The rapid-cure carbon fiber prepreg maintains storage stability equivalent to conventional products alongside a one-minute rapid cure, two attributes that are difficult to achieve simultaneously. In addition, it offers the heat resistance required for automotive parts and possesses a high degree of mechanical strength. Sample work is underway and the prepreg has already been selected for specific applications, said MCC.

About the Author(s)

You May Also Like