Two new short-glass-fiber-reinforced polypropylene (PP) compounds feature enhanced melt flow, tensile and flexural strength, and flexural modulus.

September 1, 2022

Sabic has introduced two short-glass-fiber-reinforced polypropylene (PP) compounds offering enhanced performance and processing for demanding automotive under-hood, exterior, and interior applications. Sabic’s PP compounds G3430X and G3440X are advanced grades that surpass high-performing standard short-glass-fiber materials in melt flow, tensile and flexural strength, and flexural modulus.

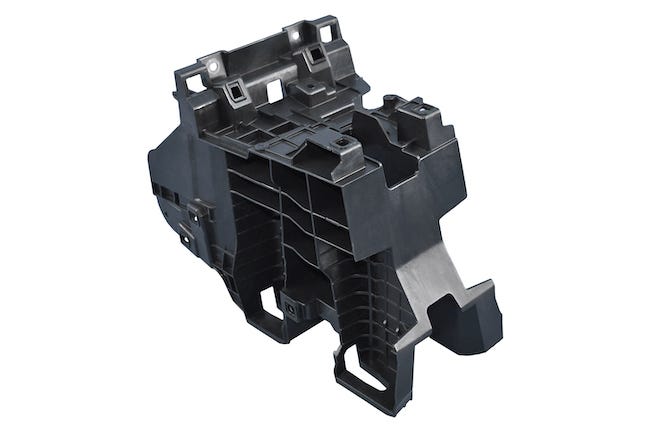

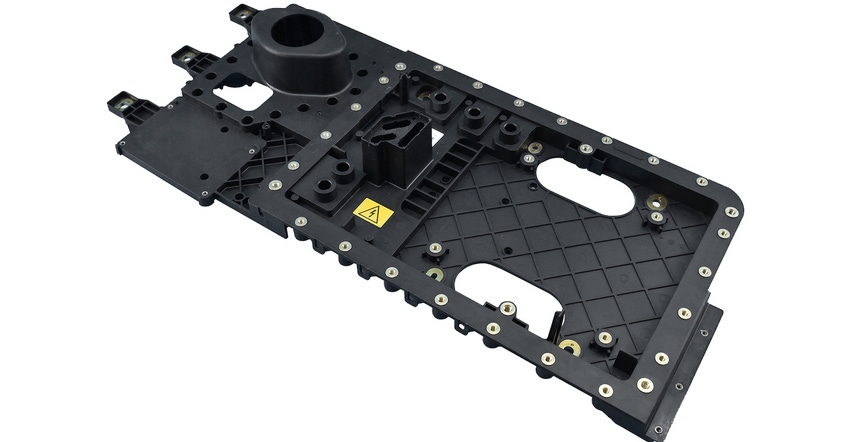

The two products give customers new opportunities to raise the performance bar for automotive structural components such as brackets, seat structures, and center consoles. Furthermore, thanks to their thin-wall capability, both materials can be used to design parts with lower mass and weight.

“Sabic’s world-class development capabilities and dedication to continuous portfolio improvement have yielded these two exceptional materials, which can empower automotive customers to significantly increase the performance of end applications,” said Abdullah Al-Otaibi, General Manager, ETP & Market Solutions. “The launch of these new Sabic PP compounds is an excellent example of our proactive response to customers’ emerging needs. We have set new industry benchmarks for robust performance and thin-wall capabilities in short-glass-fiber polypropylene, providing critical advantages in the face of escalating automotive requirements.”

Sabic PP compound G3430X grade, with 30% short glass fiber, and Sabic PP compound G3440X grade, with 40%, are said to deliver superior physical properties compared with conventional short-glass-fiber PP materials and high melt flow for easy processing. Both grades balance stiffness and impact for optimal performance in structural parts, with G3440X providing a higher degree of stiffness and greater density than the G3430X grade. In addition to offering superior performance compared with other short-glass-fiber PP compounds, these materials may be candidates for the cost-effective replacement of long-glass-fiber PP in certain low-temperature applications.

|

Sabic's new PP compounds are suited for demanding automotive applications, such as electronic component center consoles. |

Combined with stiffness and impact properties, the high melt flow of these materials offers opportunities to design thin-wall components to reduce weight without compromising overall part performance.

Reducing weight may also contribute to cost savings through the use of less material. Furthermore, cost benefits can accrue from higher productivity associated with faster cycle times, which can be enabled by higher flow.

Both Sabic PP compounds are available in standard black and natural and can be custom colored.

You May Also Like