At JEC World, the company will showcase several automotive and aerospace advances.

April 21, 2022

SGL Carbon will mark the end of its two-year hiatus from trade show attendance with multiple solutions targeting lightweighting in automotive and aerospace, among other sectors, at the upcoming JEC World exhibition in Paris on May 3 to 5, 2022. Two of the company’s business units — Carbon Fibers and Composite Solutions — will present a range of innovative carbon- and glass-fiber materials as well as tailor-made composite parts for various industrial applications.

In line with the motto of the trade fair — Composites for a Sustainable World — SGL will give attendees a taste of the sustainable solutions it has developed over the years. For example, the company is focusing on further automation of technologies for its carbon-fiber stacks for lightweight construction, while at the same time conserving resources by generating less material waste during production. In addition, it will highlight the advantages of composite materials with carbon and glass fibers in aerospace and electromobility applications. The lighter weight in composite battery cases for electric cars saves energy and, thus, ensures greater range and efficiency.

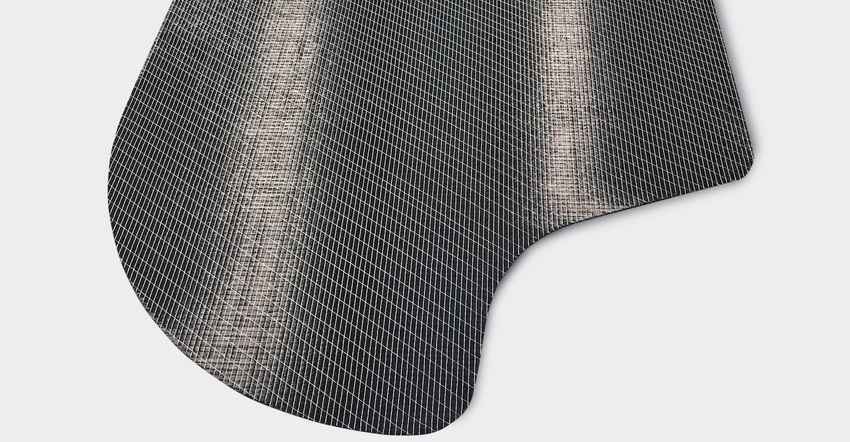

Carbon-fiber stacks tailored to customer specifications

At this year’s JEC World, SGL will present stacks of assembled carbon-fiber layers that are precisely tailored to customer specifications. SGL is working closely with customers to make component production with carbon particularly efficient and integrated in existing processes, said the company.

SGL has been producing carbon fibers, semi-finished products, and stacks for the automotive industry for more than 10 years. The material systems and production technologies have a high degree of automation and are designed so that all components can be manufactured in large production runs. Typical industry requirements from the automotive or wind turbine industries, for example, can be taken into account. An automated manufacturing process delivers high-quality stacks, while resources are conserved during production.

Further, less waste is produced compared with conventional textiles as the stack is waste optimized. Carbon-fiber stacks have been used in the side frames of the latest BMW iX models.

Composite battery cases for electric vehicles

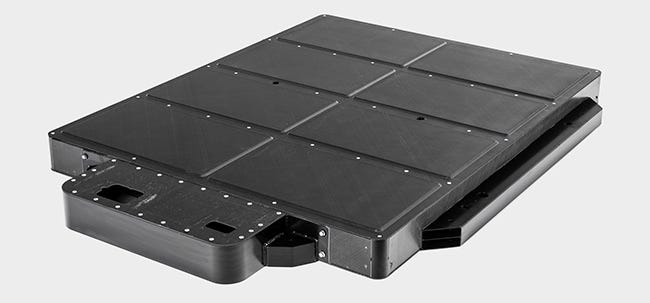

|

SGL’s high-voltage-battery housing concept represents a reduction in weight of up to 50% compared with the corresponding steel component. |

Electromobility is viewed as the solution for sustainable mobility. Batteries play a crucial role, and battery boxes made of glass-fiber and carbon-fiber composites are gaining in importance commensurately. SGL’s high-voltage battery housing concept represents a reduction in weight of up to 50% compared with the corresponding steel component. It meets high standards in terms of fire resistance, rigidity, acoustics, and both thermal and electromagnetic shielding. With fiber composites, sensors can be integrated to detect damage in the underbody of the electric vehicle.

Using carbon-fiber non-woven materials and fiber-reinforced thermosetting polymers also helps to map complex geometries with a streamlined and resource-efficient mass production process.

Impregnated materials based on glass and carbon fiber

As another example of deployment of SGL's prepreg materials, the company is demonstrating a helicopter seat reinforced with impregnated glass-fiber textiles. To this end, SGL Carbon supplies Safran Seats with various glass- and carbon-fiber prepregs. SGL developed and qualified this material individually according to the customer's specifications. The prepregs are characterized by good drapability and also meet stringent requirements for flame retardancy.

You May Also Like