Solvay Performance Polyamides introduces new Technyl polymer solutions to address the growing need for personal protection and systems safety for the automotive industry. An entire family of electro-friendly low-corroding materials has been developed to meet the needs of car manufacturers.

October 30, 2018

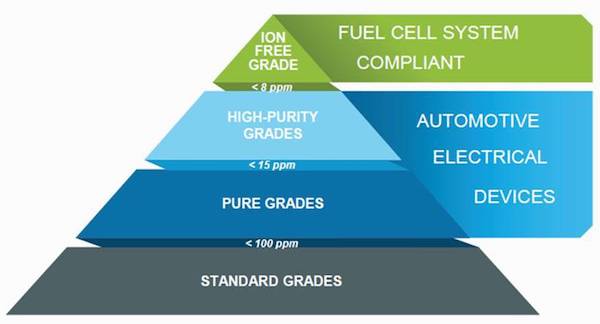

Solvay Performance Polyamides plans to introduce a range of six Technyl and Technyl Star polyamide (PA) grades offering high degrees purity based on dedicated formulations and clean compounding. Two of these grades use bio-based, eco-friendly Technyl eXten technology for applications needing high temperature combined with glycol resistance. The range will be commercially available early 2019.

“Halogens and phosphorus contained in PA have been identified as major contributors to galvanic corrosion, a potential source of system failure and short-circuits which could lead to fire,” says Dr. James Mitchell, Automotive Market Director for Solvay’s Performance Polyamide global business unit. “Safety is not an option! We have developed a range of materials with high levels of purity to help automotive OEMs and Tier 1 suppliers ensure the protection of systems from corrosion and ionic migration.” Automotive applications requiring these solutions include electrified cooling systems, sensors and connectors, as well as high-power EV chargers.For fuel cell stack components, Technyl One has emerged as a preferred material choice, offering more value to customers when compared to polyphthalamide (PPA) compounds in terms of both in-use performance and processability. This material combines a near-zero ion migration potential with outstanding heat resistance, dimensional stability against hydrogen leakage, electrical insulation, high surface aspect and weldability.

“This is the first PA 66-based offer on the market specifically designed for fuel cell technology. It serves critical safety applications such as hydrogen manifolds, heater plates, humidifiers and water traps,” added Mitchell.

In addition to these advanced material solutions, Solvay Performance Polyamides offers a complete array of technical services designed to speed the time to market of new applications. This offering includes predictive simulation with MMI Technyl Design, 3D printing of functional prototypes in Sinterline PA6 powders, as well as part testing at fully equipped APT Technyl Validation centers located in Lyon, France and Shanghai, China. MMI Technyl Design is an advanced service powered by Digimat from e-Xstream, an MSC Software Company.

|

Technyl offers OEMs a range of electro-friendly products to adapt purity needs to the diversity of application requirements. Graphic courtesy of Solvay Performance Polyamides. |

About the Author(s)

You May Also Like