The company’s move to offer commodity engineering plastic prepregs will boost appeal to automakers.

March 4, 2022

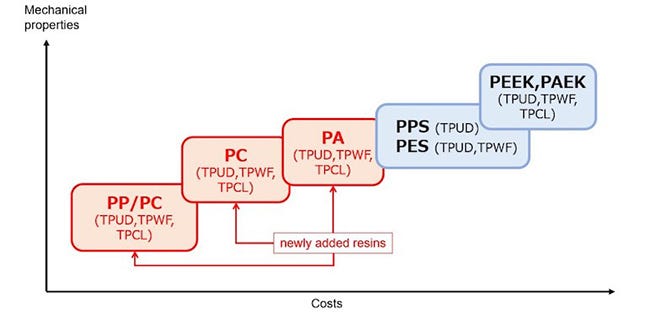

Until recently, Japan’s Teijin has offered high-performance carbon-fiber prepegs using advanced engineering plastics such as polyetheretherketone (PEEK), polyaryletherketone (PAEK), and polyethersulfone (PSE), as well as polyphenylene sulfide (PPS). To further its aspirations to expand carbon-fiber composite usage in the auto sector, Teijin is now offering three additional matrix materials: Polypropylene (PP)/polycarbonate (PC), PC, and polyamide (PA).

These are now being used as base resins in new versions of the company’s existing prepreg products, including Tenax ThermoPlastic UniDirectional (TPUD), Tenax ThermoPlastic Woven Fabric (TPWF), and Tenax ThermoPlastic Consolidated Laminate (TPCL).

Compared to Teijin’s existing thermoplastic intermediate materials made with PEEK, PAEK, PPS, and PSE resins, prepregs made with the three new thermoplastic resins can be molded at lower temperatures for faster and more cost-effective production, making them suitable for applications requiring production efficiency, such as automobiles, sporting goods, and precision instruments.

|

Cost in relation to mechanical properties of thermoplastic resins used in carbon-fiber intermediates. |

About the Author(s)

You May Also Like