Durability, robustness and scratch resistance issues addressed for soft-touch surfaces in automotive interior applications.

August 28, 2020

Kraiburg TPE is taking up the trends and challenges involved in mobility becoming increasingly connected, electrified and automated, with two material series that focus particularly on the increasing requirements of automotive interior components. FG/SF and VS/AD/HM series Thermolast K compounds meet the quality standards for durability, robustness and scratch resistance of soft-touch surfaces for automotive interior applications. A new compound for cost-conscious implementation of shelf mats complements the portfolio.

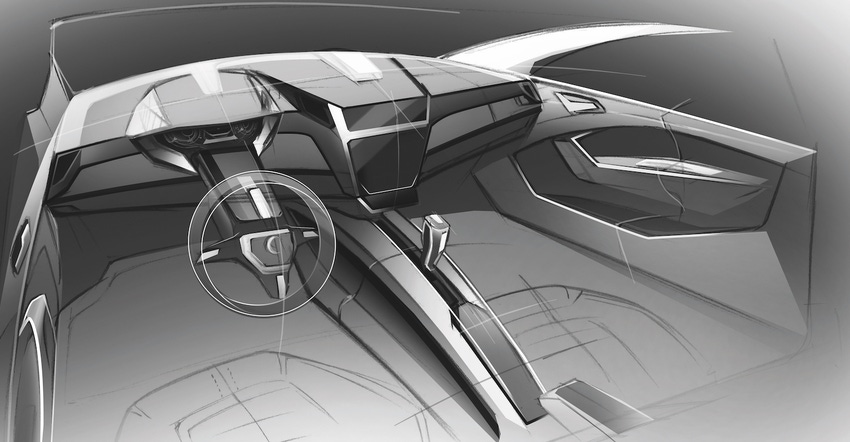

The automotive industry is in transition: Trends such as in-vehicle infotainment (IVI) set high standards for long-lasting aesthetics, colorfastness, durability and cleanability of visible surfaces. At the same time, materials used for interior vehicle components not only have to meet increasingly strict and partly regional standards and specifications in terms of odor and emissions, but preferences depending on the manufacturer also play a crucial role. To be able to supply customers from a single source, Kraiburg TPE has extended its compound portfolio for soft-touch surfaces for automotive interior applications.

As components for visible areas often set exacting standards for materials due to varying sizes and geometries, Kraiburg TPE has developed the FG/SF (Fogging/Surface-Finish) series featuring:

Excellent flowability allowing stress-relieved filling with complex component geometries, low wall thicknesses or large variations in wall thickness.

Flawless surface quality: Perfect surfaces, even at low processing temperatures.

Reduced pressure peaks: The risk of distortion or waviness is reduced.

High dimensional accuracy and reproducibility.

Consistent odor properties in accordance with VDA 270 B3, with a score of 3.0 for all hardnesses from 50 to 80 Shore A.

Extra robust for everyday use.

All of these properties reportedly make compounds from the FG/SF series an ideal material for all insert mats and shelf mats for center consoles, instrument panels, glove boxes, door pockets, and roof liners.

The VS/AD/HM (Velvet Surface/Adhesion/High Mechanical Properties) series is adhesion-promoted. Compounds in the series deliver adhesion to polar thermoplastics such as polycarbonate (PC), ABS, ABS/PC, ASA, and SAN, and to polyamide (PA) 6 or PA12 polyamides. Further advantages are:

TPU-level scratch and abrasion resistance combined with compliance with established OEM standards such as those involving emission and odor;

Resistance to sebum oils, creams and automobile-specific cleaning agents;

Velvety touch;

Good processability.

Typical applications are multicomponent parts ranging from anti-slip mats in cup holders to soft-touch surfaces of center console covers, seat belt buckles and door pull handles through to shelves that include an integrated, inductive charging option for cell phones. The VS/AD/HM series also provides a unique selling proposition in terms of scratch and abrasion resistance for single-component parts such as shelf mats for visible areas, thus making the series an important materials solution for OEMs that require the highest level of quality.

In addition, Kraiburg TPE is has launched the GP/HF series of compounds combining enhanced flowability with an attractive cost-performance ratio, while maintaining consistent quality. Kraiburg TPE is thereby making a major effort to support the automotive industry in coping with high cost pressures.

“Our aim was to be able to provide the best possible materials in terms of properties and cost-performance ratio,” says Alexander Mayer, Team Automotive Application Development expert for interior applications, summing up. “And we’ve succeeded in achieving that. Our product portfolio enables us to fulfill all current and future customer requests.”

About the Author(s)

You May Also Like