Automotive air-conditioning hose made of rubber–resin polymer alloy combines flexibility and heat resistance of rubber with gas-barrier properties of resin.

August 17, 2021

The Yokohama Rubber Co. Ltd. has developed a hybrid material that significantly reduces the weight of automotive air-conditioning hoses. The company is now accelerating the development of a commercial product and aims for a full market launch in 2024.

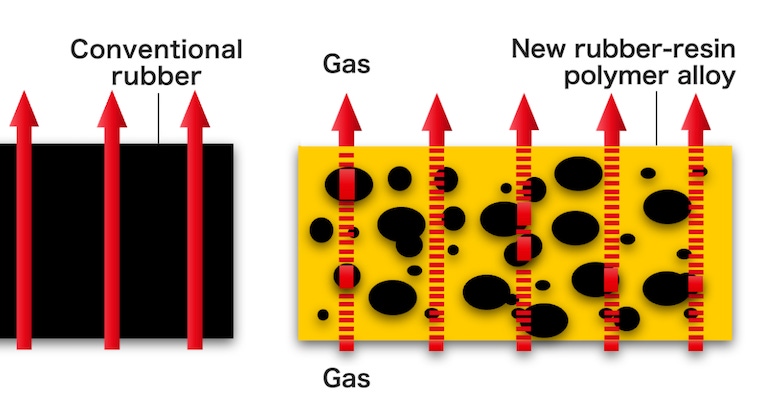

The new ultralight hose is made from a rubber–resin polymer alloy with a sea-island structure in which the sea phase is composed of resin and the island phase is composed of rubber. This new alloy combines the flexibility and heat resistance of rubber with the gas-barrier properties of resin; its use enabled Yokohama Rubber to reduce the hose’s weight by 50%. Gas-barrier properties are also superior compared with conventional all-rubber hosing, said the company.

Hoses made using this alloy do not require vulcanization. Further, Yokohama Rubber plans to develop and promote all-resin piping to achieve a significant reduction in the weight of hose and pipe combinations. While continuing to develop a commercial version of this new lightweight hose, Yokohama Rubber also aims to enter the market for other types of automotive pipes.

About the Author(s)

You May Also Like