With automotive regulations governing fuel economy and CO2 emissions being discussed globally, nearly half of automotive engineers predict those regulations will strengthen, according to a WardsAuto and DuPont (Wilmington, DE) survey conducted in July this year. Only eight percent predict regulations will relax, primarily due to economic and cost issues, and one-fourth expect no change, the results show.

August 26, 2013

With automotive regulations governing fuel economy and CO2 emissions being discussed globally, nearly half of automotive engineers predict those regulations will strengthen, according to a WardsAuto and DuPont (Wilmington, DE) survey conducted in July this year. Only eight percent predict regulations will relax, primarily due to economic and cost issues, and one-fourth expect no change, the results show.

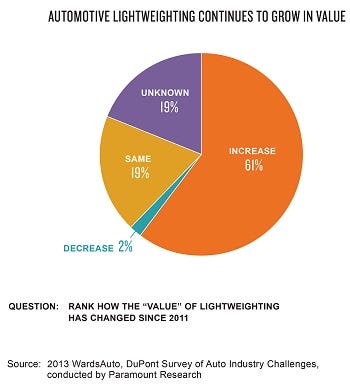

The survey results also show the value for lightweighting vehicles to help meet targets is increasing, and that every system in the vehicle is a candidate for reduced mass.

"Fuel and emission standards throughout the world are driving significant changes in vehicle design," said DuPont Performance Polymers President Diane H. Gulyas. "There are multiple solutions simultaneously getting into the market and the industry must continue to work in harmony to develop low emission, fuel-efficient vehicles that consumers want to drive."

Now in its third year, the annual survey with WardsAuto was conducted as the European Union delayed a vote to adopt stringent 2020 emission regulations. This uncertainty, coupled with the mid-term evaluation process built into the 2017-2025 U.S. regulations, stimulated a survey asking subscribers to weigh in on the outcome and whether their companies are reacting to uncertainties. More than 1,300 subscribers to industry publication WardsAuto responded to the survey. Forty three percent say there are no changes, 36 percent say there are some or many changes in the development pipeline.

|

|

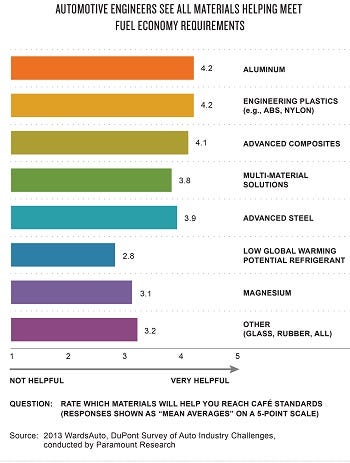

While last year's respondents gave aluminum a slight edge over plastics and composites as the material that can best help them meet regulations, respondents today are looking at all materials in the portfolio

In 2011 surveys with the Society of Automotive Engineers and WardsAuto, the automotive engineering community revealed that materials are critical to a product's success, yet most said they were not confident that today's materials portfolio would help them meet CAFE regulations.

"We've seen a variety of materials-based solutions introduced in the past couple years," said Mike Day, DuPont Automotive Performance Polymers development director in North America. "And development activity with the automakers is intensifying, especially related to new composite and multi-material solutions that deliver the strength and stiffness needed for performance and safety."

Last month DuPont highlighted a developmental composite technology called DuPont Vizilon in a PSA Peugeot Citroen side-impact door beam. This developmental thermoplastic composite technology showed a 40 percent weight reduction compared to ultra-high strength (UHHS) steel and absorbed more energy than metal and short glass-fiber polymer beams to pass the PSA Peugeot Citroën's crash test.

"Speed is critical," said Day "but not at the expense of performance and safety. We believe that close collaboration on these new technologies is more important than ever before. Each of us brings to the table a deep knowledge and different perspective. The synergy experienced when we converge is the catalyst that sparks the breakthrough."

Lightweighting is core to meeting new standards and one that is growing in value, according to more than 60 percent of respondents. Further, when asked which systems are the most likely targets - all ranked relatively equally. "The results reflect that every system, every component throughout the vehicle is a candidate for weight savings," said Day. "This is a great time to incorporate plastics early in the design stage since there are many more opportunities to integrate functions for significant mass and cost savings."

In addition to lightweighting, the industry continues to optimize the internal-combustion engine, develop hybrid and electric vehicles and adopt alternative fuels, which also has implications for plastics usage, particularly as under-the-hood temperatures are on the rise. "The challenges facing the automotive community are so significant and global that they must be attacked from multiple angles simultaneously, tapping into global teams for support and fresh ideas," Gulyas added.

About the Author(s)

You May Also Like