Sponsored By

Auxiliaries

ultrasonic welder

Auxiliaries

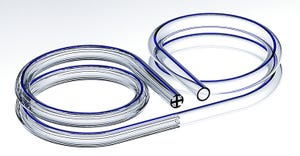

Next-gen Ultrasonic Welders Have Plastics FixationNext-gen Ultrasonic Welders Have Plastics Fixation

Rinco Ultrasonics aims to show NPE attendees how they can improve efficiency and productivity with next-gen pneumatically driven ultrasonic welding technology.

Sign up for the PlasticsToday NewsFeed newsletter.