Ultrasonic welding equipment maker Rinco Ultrasonics has added 4000 square feet to its operations, hired three additional employees, and installed new machinery.

October 5, 2020

Ultrasonic welding equipment maker Rinco Ultrasonics has announced a significant expansion of tooling capabilities at its Danbury, CT, headquarters. The company has added 4000 square feet to its operations, hired three additional employees, and installed new machinery.

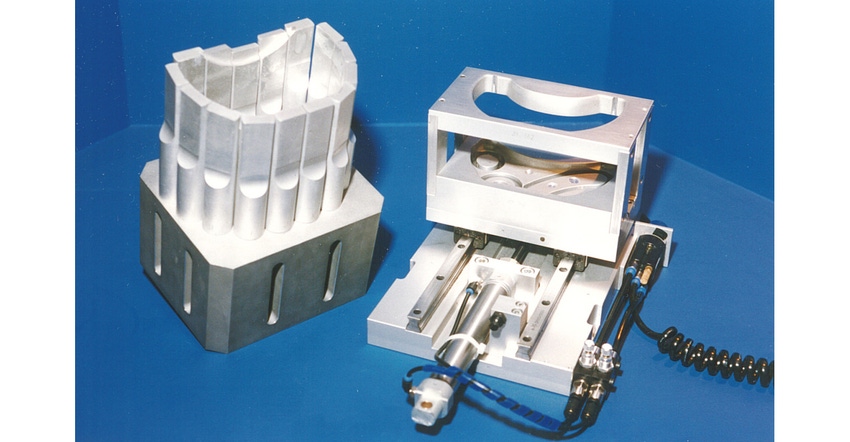

The expansion is in response to growing demand for faster deliveries and to satisfy highly complex welding applications for the automotive and medical markets, the company explained. Ultrasonic tooling has been brought in-house to ensure complete control of documentation, testing, and other key program functions for customers.

“The continual need for highly complex and precise tooling represents a major opportunity for our company,” said Steve Potpan, on-site manager for Rinco Ultrasonics. “We’re confident that this investment in personnel, space, and manufacturing resources will give us a huge amount of flexibility to meet market demand.”

The company purchased a Haas CNC milling center, a Trak lathe with a Proto Trak SLX controller, and several Trak K3 knee mills. New personnel include two full-time machinists and one full-time design engineer, who also fills in as a part-time machinist.

According to Rinco, the ultrasonic welding market is witnessing greater demand for large composite horns with multiple elements. These include mother horns measuring up to 300 mm, with multiple extenders ranging from 2 to 20 mm that incorporate three-dimensional contours and milled geometries.

Rinco’s experienced staff uses Solidworks CAD design software in conjunction with CAMWorks to create the tool path for the CNC equipment. The design process also incorporates the use of Ansys finite element analysis.

Rinco reports strong interest in its new tooling capabilities from leading US processors and manufacturers.

About the Author(s)

You May Also Like