The Branson MCX series ultrasonic mold cleaning system increases productivity, improves cleaning effectiveness, and prevents damaging costly molds.

July 14, 2021

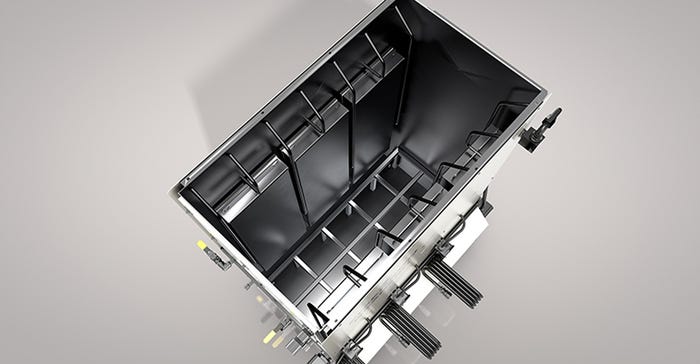

The new Branson MCX Series ultrasonic mold cleaning system from Emerson is designed with side-mounted immersible transducers and powerful immersion heaters for fast and efficient operation. Compared with manual cleaning of plastics injection molds, which may take up to three hours or more, the Branson MCX Series does a more thorough job in 15 to 20 minutes, depending on mold design and level of residue.

The Branson units are purpose-built for cleaning injection molds, which is why the side-mounted transducers represent an important innovation compared with transducers mounted on the bottom of the tank, said Emerson. Since most plastic injection molds are rectangular, with many design details on the surface facing the side of the tank, side-mounted transducers produce more intense and focused cavitation than bottom-mounted transducers. Cleaning is more effective and takes less time.

|

The Branson MCX Series ultrasonic cleaning system for injection molds features side-mounted immersible transducers and powerful immersion heaters. |

"Manual scrubbing is still the most commonly used method for cleaning plastic injection molds, but it is highly labor intensive and can take two or three hours," noted Nitin Phadnis, Director of Emerson´s welding and assembly business. "Even then, the end result may not be as good or predictable as ultrasonic cleaning, which takes just 15 to 20 minutes and dramatically reduces the risk of damaging intricate mold design details."

Moreover, manual cleaning typically requires high concentrations of often-toxic solutions, brushes, and other tools. Branson's systems use non-contact ultrasonic technology to produce fluid cavitation. Mold halves are placed between the transducers mounted on opposite sides of the tank, which is filled with a cleaning solution. The system emits ultrasonic waves into the solution, creating minute bubbles (or cavities) that eventually implode, releasing tremendous amounts of energy. The resulting turbulence dislodges contaminants from the mold surface as well as blind holes and tiny crevices that brushes cannot reach. The cavitation turbulence enhances the effectiveness of the cleaning chemicals and results in better release, improved productivity, less maintenance, longer mold life, and reduced chemical waste, said Emerson.

The MCX Series cleaners are pre-configured in three stock tank sizes to accommodate small molds (up to 24 x 24 x 10 in.), medium-sized molds (up to 38 x 38 x 14 in.) and molds as large as 52 x 48 x 17 in. The side-mounted immersible transducers can deliver cavitation in 25 and 40 kilohertz frequencies. In addition, the MCX Series can be configured to include one or more rinse stations to remove latent chemistries and add rust-inhibiting chemistries to improve mold life and performance.

About the Author(s)

You May Also Like