March 28, 2016

Sefortek Inc. (Stoney Creek, ON, Canada) has announced the availability of an ultrasonic welding system for painted parts. Initially designed for an automotive-related task, the machine performs 14 welds, but it can be modified for various applications. Key features of the system include:

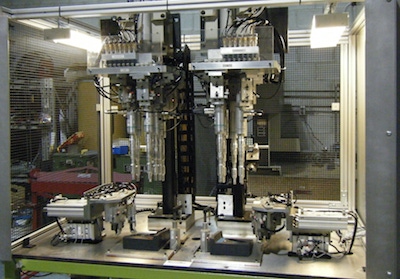

Sefortek Inc. (Stoney Creek, ON, Canada) has announced the availability of an ultrasonic welding system for painted parts. Initially designed for an automotive-related task, the machine performs 14 welds, but it can be modified for various applications. Key features of the system include:

Vision sensors for the left- and right-hand nests, which can be enabled or disabled by the user, detect the presence of three clips, double sided tape and clip foam. Extra sensors in the nest detect the presence of plastic and aluminum chrome parts.

A light fixture is on by default, but it can be disabled by the user. If it is disabled, a message on the user interface alerts the operator. It has to be turned on in order for the machine to operate.

The urethane nests have blue rubber strips that protect the paint, preventing the formation of blemishes.

Height-adjustable heat sinks under the two inner posts are made of brass to dissipate heat and prevent paint blemishing.

A light curtain in front of the machine ensures operator safety. A back-door interlock switch prevents the machine from running if the door is open.

The ultrasound welding system has three power generators. Three multiplexer cards on an auxiliary panel enable switching of the power generators from post to post. Welding is controlled by time. Amplitude can be left at 100%, with a simple time adjustment to achieve a lower or higher post weld. Energy is used only as guidance: The energy level can be set in order to make sure a weld has been completely made.

About the Author(s)

You May Also Like