A white paper from Optris explains how non-contact IR temperature sensing can benefit extrusion, injection molding, and thermoforming operations.

May 23, 2022

A lot can go wrong with temperature measurement during plastics processing and, by extension, the quality of your finished product. Even if you do everything by the book, errors can originate from ambient conditions. A new white paper from Optris explains how non-contact infrared (IR) temperature measurement technology can help to overcome these challenges.

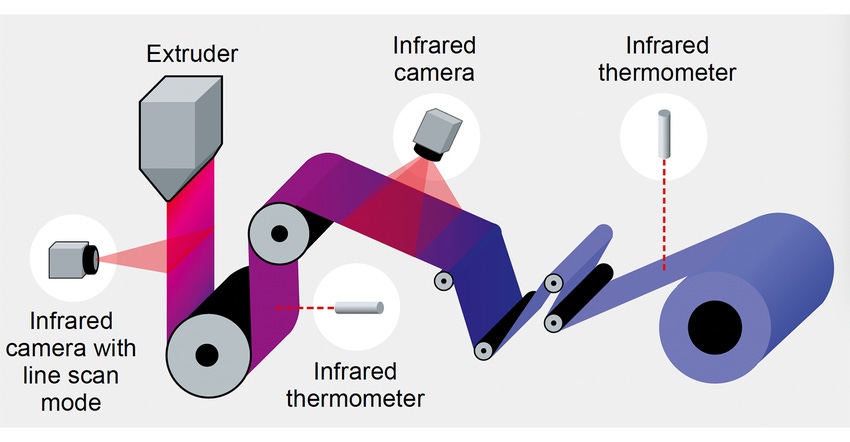

Plastics processors make products in various dimensions, thicknesses, textures, colors, and embossed patterns, notes the white paper. Manufacturing is subject to numerous thermal processes that must be continually and rigorously checked at various critical points. The paper provides in-depth explanations of how IR temperature sensing can benefit flat film and sheet extrusion, injection molding, rotational molding, extrusion and stretch blow molding, and thermoforming. A particular focus is improved measurement of thin-film plastics.

The white paper, “Non-Contact IR Temperature Measurement Applications for Plastics Challenges,” is available as a free download (registration required).

You May Also Like