DSM Dyneema (Heerlen, The Netherlands) has announced plans to invest in a technical center in Singapore, which will house the nation's first independent ballistic testing center.Ballistic facility will develop and test vehicle armor, among other life protection applications.

October 10, 2011

DSM Dyneema (Heerlen, The Netherlands) has announced plans to invest in a technical center in Singapore, which will house the nation's first independent ballistic testing center.

|

Ballistic facility will develop and test vehicle armor, among other life protection applications. |

The center is scheduled to be fully operated in the fourth quarter of 2012 and provide testing and technical support services for the company's ultra high molecular weight polyethylene (UHMWPE) Dyneema fiber, tape and uni-directional fabric and composite sheet materials in the Asia Pacific region focused on life protection applications including vehicle armor.

"Our partnership with the Singapore Economic Development Board through their Innovation Development Scheme has been instrumental in DSM Dyneema's decision to establish the Centre here," commented Gerard de Reuver, President of DSM Dyneema. "The APAC Technical Centre is DSM Dyneema's third global ballistics testing facility and our first such center in Asia Pacific. It will also be home to the regional headquarters for DSM Dyneema Life Protection business," added Marco Kleuters, Vice President of Life Protection APAC.

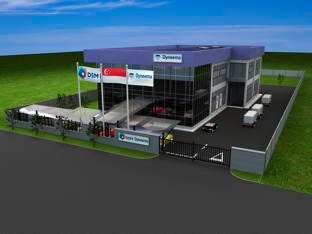

The 2500-square meter APAC Technical Centre will incorporate a basement housing two ballistic testing ranges as well as equipment and testing labs where technicians will be able to conduct comprehensive tests on personal and vehicle protection applications with Dyneema in accordance with international, European and regional Asia Pacific standards.

It will also drive research and development as part of DSM Dyneema's Fiber Solutions global R&D facility by supporting new application development and enhancing technological capabilities for APAC customers as well as developing and driving new application areas like renewable energy in the region.

The Technical Centre is designed and constructed in line with DSM Dyneema's commitment to sustainability by aligning itself with Singapore's Building Construction Authority (BCA) Green Mark Scheme. It incorporates green building technologies resulting in a high-level of energy efficiency and sustainable work environment.

Dyneema fiber offers maximum strength combined with minimum weight. It is up to 15 times stronger than quality steel and up to 40% stronger than aramid fiber, both on weight-for-weight basis. Dyneema fiber floats on water and is extremely durable and resistant to moisture, UV light and chemicals. One major application is panels in military vehicles that provide added protection at low additional weight.

Dyneema fiber is produced in Europe in Heerlen, and in North America in Greenville, North Carolina. DSM Dyneema is also a partner in a high modulus polyethylene (HMPE) manufacturing joint venture in Japan.-[email protected]

About the Author(s)

You May Also Like