According to battenfeld-cincinnati (Vienna), both newcomers and experienced processors of wood-plastic composites (WPC) have benefitted from the cooperative research agreement between battenfeld-cincinnati Austria and the research institute Kompetenzzentrum Holz GmbH (Wood K plus), headquartered in Linz, Austria, since 2008. This cooperation agreement, a part of the Comet program organized by the Austrian Research Promotion Agency FFG, will now be extended for another eight years and further intensified.

October 20, 2015

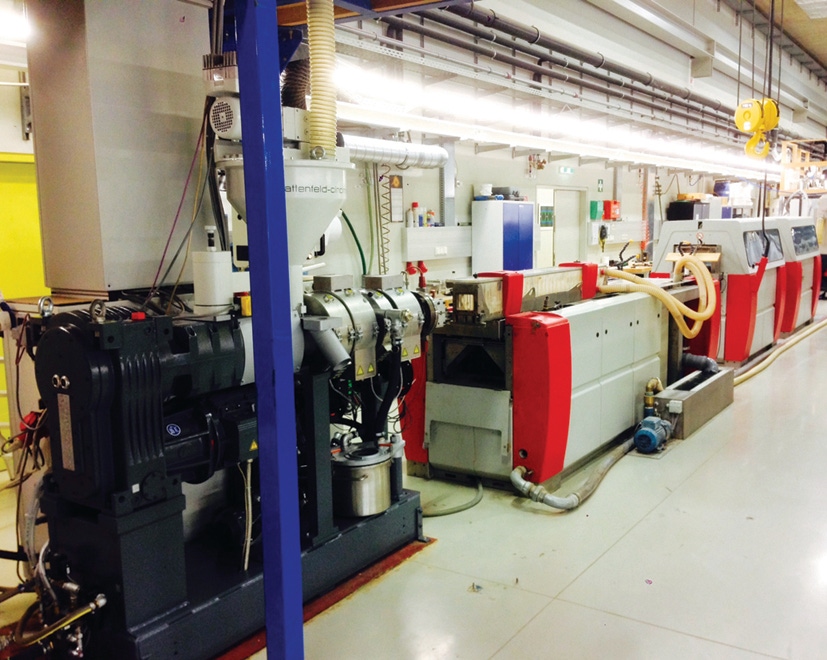

According to battenfeld-cincinnati (Vienna), both newcomers and experienced processors of wood-plastic composites (WPC) have benefitted from the cooperative research agreement between battenfeld-cincinnati Austria and the research institute Kompetenzzentrum Holz GmbH (Wood K plus), headquartered in Linz, Austria, since 2008. This cooperation agreement, a part of the Comet program organized by the Austrian Research Promotion Agency FFG, will now be extended for another eight years and further intensified.  Machine manufacturer battenfeld-cincinnati has completely overhauled the WPC extrusion line used by Wood K plus and brought it up to the latest technological standard. This means that even more flexible methods of processing materials with natural fiber content can be realized—in both one-step and two-step processes.

Machine manufacturer battenfeld-cincinnati has completely overhauled the WPC extrusion line used by Wood K plus and brought it up to the latest technological standard. This means that even more flexible methods of processing materials with natural fiber content can be realized—in both one-step and two-step processes.

With its fiberEX 38, Wood K plus operated the smallest production-scale extruder form battenfeld-cincinnati’s conical twin screw extruder series specially designed for processing WPCs. Many projects have already been implemented under the research cooperation agreement, resulting in an enormous amount of process know-how and extensive knowledge about suitable formulations for a wide range of different WPC products. Alternative fiber materials have also been processed, such as cork, bamboo, help, straw and many others. Innovative processes have been tested such as WPC foaming, and the question “how much conventional fiberboard could be replaced by WPC” is currently being investigated. The final assessment of all extrusion test results is carried out at the institute’s own physical, technological and analytical test lab.

In part as a result of this cooperative agreement with its research partner, battenfeld-cincinnati has repeatedly  succeeded in further improvements in its WPC processing methods. The fiberEX 38, installed at the beginning of the first project period has now been brought up to the latest standard of technology and retrofitted with a new, optimized screw geometry and a new degassing unit. Thanks to its intelligent design, the new degassing unit prevents the release of dust particles from the process chamber and simultaneously ensures a highly effective degassing performance.

succeeded in further improvements in its WPC processing methods. The fiberEX 38, installed at the beginning of the first project period has now been brought up to the latest standard of technology and retrofitted with a new, optimized screw geometry and a new degassing unit. Thanks to its intelligent design, the new degassing unit prevents the release of dust particles from the process chamber and simultaneously ensures a highly effective degassing performance.

This extrusion line is able to produce not only compounds for later use in extrusion or injection molding processes, but also WPC profiles in on- or two-step processes when fitted with a suitable die and matching downstream equipment. Since the fiberEX 38 is a production-scale line, up-scaling to a larger production line presents no problems. Consequently, the project constitutes a win-win symbiosis between the industrial partner and the research institute, said battenfeld-cincinnati’s information.

This new WPC line combined with the consultancy services of battenfeld-cincinnati and Wood K plus is ideal for customers who are interested in innovative WPC products, but have no facilities of their own to implement R&D projects or develop new compounds, or who need well-founded data concerning plausibility and feasibility before entering the market themselves with a new product.

About the Author(s)

You May Also Like