In conjunction with the recent Chinaplas trade show, battenfeld-cincinnati China (Shunde) organized two demonstrations, presenting two lines in production: A high-output line for 400-mm gas pipe extrusion and a LeanEX high-speed line for 20-mm PE-RT pipe running at a line speed of 40 m/min. Both lines showcased technical competence and energy efficiency in production, said the company.

July 8, 2015

In conjunction with the recent Chinaplas trade show, battenfeld-cincinnati China (Shunde) organized two demonstrations, presenting two lines in production: A high-output line for 400-mm gas pipe extrusion and a LeanEX high-speed line for 20-mm PE-RT pipe running at a line speed of 40 m/min. Both lines showcased technical competence and energy efficiency in production, said the company.

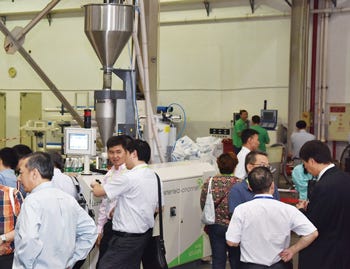

More than 200 visitors went to the Shunde plant for presentations and extrusion line demonstrations. The 400-mm solEX 75 single-screw extruder for gas-pipe production has a standard AC motor that offers 20% energy savings compared with a DC motor and achieves 1,200 kg/hour output with a noise level below 80 db.

More than 200 visitors went to the Shunde plant for presentations and extrusion line demonstrations. The 400-mm solEX 75 single-screw extruder for gas-pipe production has a standard AC motor that offers 20% energy savings compared with a DC motor and achieves 1,200 kg/hour output with a noise level below 80 db.

The helix 400 VSI-T pipe head with inner-pipe efficient air cooling ensures optimum melt homogeneity and pipe quality, with minimal sagging. The combination of solEX and helix VSI-T is also ideal for large-diameter solid PO pipe extrusion, claims the company, noting that diameters up to 2.6 m are possible. The inner cooling in the pipe head also enables an impressive 45% reduction in line length from 85 to 47 m.

The second line on display was a LeanEX system, which is available in five sizes: 63, 160, 250, 400 and 630 mm. The LeanEX concept stands for "lean extrusion" and is built for the Chinese market. The line shown was a LeanEX 63-mm line with a LeanEX C1-60-30 single-screw extruder producing a PE-RT pipe in dimensions of 2.3 mm. The system achieves a line speed of 40 m/min and an output of 320 kg/h.

The HDPE XSene XRT 70/ RE-RT Type II material for the line was sponsored by Total Refining & Chemicals.

About the Author(s)

You May Also Like