Applications for its first product, amorphous polyhydroxyalkanoate (aPHA), a softer, more rubber-like version of PHA, include rigid and flexible packaging.

CJ Bio, now known as CJ Biomaterials, acquired polyhydroxyalkanoate (PHA) pioneer Metabolix in 2016. Earlier this year, the company's amorphous PHA (aPHA), went into production with the startup of a new production facility in Indonesia.

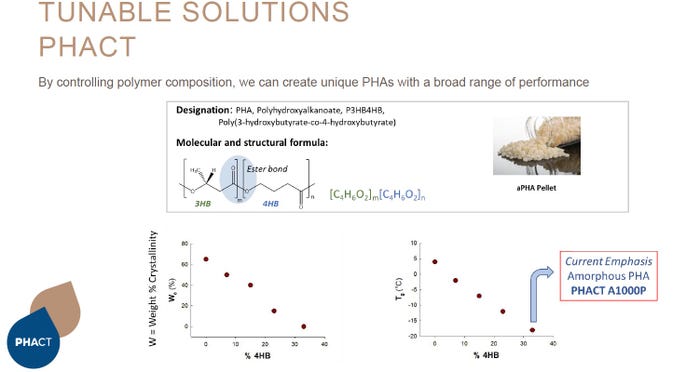

Designated as PHACT A100P, aPHA is the bioplastic supplier’s initial launch from a technology platform for “tunable” designer biopolymers that can also enhance other bioplastics.

Why aPHA? According to CJ Biomaterials, it's a softer, more rubber-like version of PHA that offers fundamentally different performance characteristics than crystalline or semi-crystalline forms of PHA.

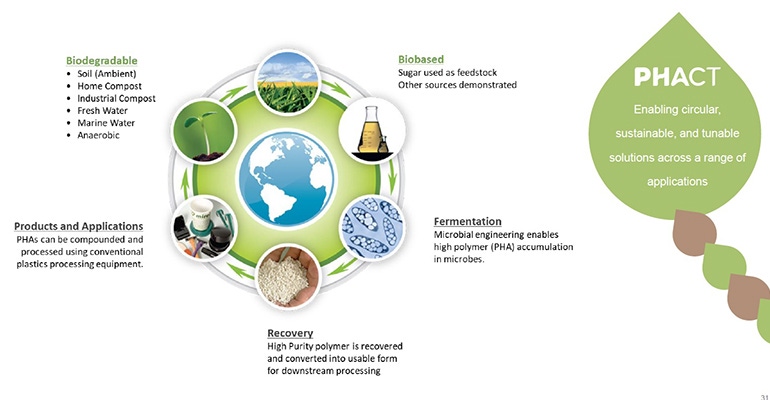

Made from plant sugars like sugarcane, tapioca, corn, and cellulosic biomass, aPHA is certified biodegradable under industrial compost, soil (ambient), and marine environments.

aPHA is also considered home compostable — it does not require specialized equipment or elevated temperatures to be fully biodegradable.

Max Senechal, the company’s chief commercial officer, references data published by organizations such as EUPB that forecast rapid growth in the market, in this instance expanding from about 2 million tons in 2020 to more than 7 million tons by 2026.

A report released this month by Prophesy Market Insights agrees, forecasting a CAGR of 22.4% for biopolymers. The report expects the market to increase in value fom $10.7 billion in 2022 to $86.7 billion by 2032.

That aggressively optimistic projection is seen in brand owner traction.

“We see a very strong push from brand owners moving from [biopolymer] interest to adoption as evidenced by organizations such as PepsiCo’s Off the Eaten Paths snacks, to Bacardi and more recently, upstart companies such as Cove with a biodegradable water bottle,” Senechal tells us. “Once thought of as aspirational, PHA is now seen as responding to the consumer voice in many cases.

“Additionally, transformative regulatory projects such as [California’s] SB 54 will pave the way for comprehensive circular solutions where biopolymers play a big role.”

There is growing activity on the new business front as well. CJ Biomaterials has announced arrangements with Accor hotels, Yuhan-Kimberly, and NatureWorks to develop products using aPHA.

CJ Biomaterials has also partnered with South Korea Ministry of Science and ICT (MSIT) and the Korea Innovation Foundation (INNOPOLIS) to actively promote eco-friendly materials, including PHA.

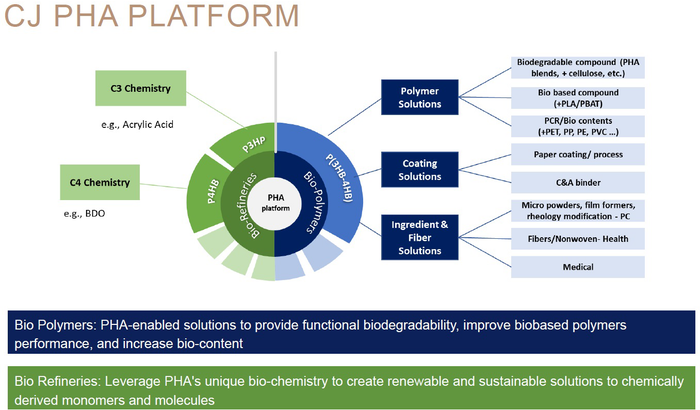

New markets and property-improving blends with PLA.

CJ Biomaterials’ near-term focus is developing aPHA for rigid and flexible packaging, which account for more than 50% of single-use plastics.

“It’s suitable for packaging in markets including food, beverages, personal care, consumer goods, healthcare, automotive — all areas where better sustainable solutions can have a positive impact on the challenge of plastic waste,” Senechal points out.

Other potential markets include agriculture, organic waste management, coatings, and adhesives.

“We’ve seen a high level of attention with our PHACT A1000P and have moved this through trials to improve performance and end-of-life solutions,” Senechal reports.

“aPHA can also be used as a modifier for other compostable polymers and biopolymers to increase bio-based content, accelerate biodegradation, and improve functional properties of resins and finished products.”

Keen interest in biopolymers prompted a dramatic turnaround in how Senechal views the competition.

“We want to see all biopolymers succeed first and foremost,” he says. “The competitive environment is shifting from ‘Who has the better technology?’ to ‘How can these technologies work together to find solutions that are needed’?”

In fact, the company’s first product is a perfect example of this change, Senechal says. “We’re excited about a collaboration with NatureWorks to develop multiple new compounds that can expand the field of applications for biopolymers by leveraging the unique features of polylactic acid and aPHA.”

Blending aPHA with PLA biopolymers leads to significant improvements in mechanical properties, such as toughness and ductility, while maintaining clarity and improving its biodegradability.

“Based on the voice of the market we’re getting right now, we’re very positive about the growth potential of aPHA,” Senechal says.” As the market continues to adopt biopolymers, we’re confident that aPHA will play a key role in this expansion.”

Additional new products will leverage the company’s custom tunable polymer capabilities soon.

“The company plans to launch in 2023 a semi-crystalline PHA (scPHA) product as well as additional capacity for our aPHA,” Senechal discloses.

The company’s future appears as sustainable as its products.

About the Author(s)

You May Also Like