EU packaging waste directive may inhibit growth of bio-based polyolefin market in Europe.

January 23, 2023

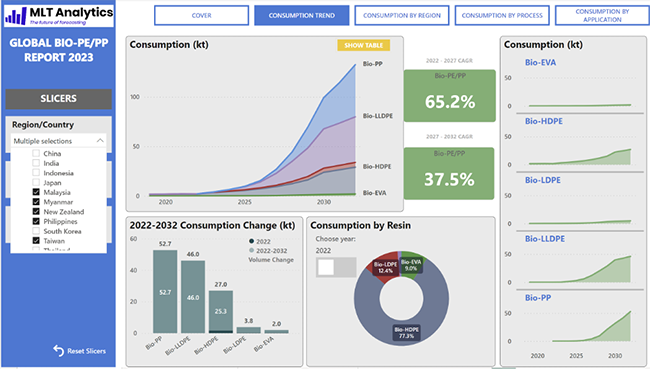

The global market for bio-based polyolefins is forecast to multiply by a factor of more than 20 between 2022 and 2032, reaching a volume of more than 4.7 million tonnes, according to a report released by business intelligence firm MLT Analytics. This impressive growth is set to be fueled by a variety of end uses, including existing mainstream bio-polyethylene applications such as extrusion coating, shopping bags, and blow-molded containers, and emerging bio-polypropylene applications such as hygiene, housewares, and rigid and flexible packaging.

“2022 was a breakout year for bio-polyolefins, in that we saw a notable diversification in the supplier base, with emerging suppliers developing and augmenting their commercial presence in the market, and adding to the dominant presence of incumbent producer Braskem,” said MLT Analytics CEO and co-founder Stephen Moore. “We also saw the bio-PP market more than triple in scale between 2021 and 2022, as mass balance-based polymer production kicked off in Europe and Japan,” he added.

|

The Asia Pacific region is forecast to emerge as the leading consumer of bio-polyolefins by 2032. |

Most global polyolefin suppliers have announced sustainable polyolefin targets, typically to be achieved by 2030, that involve a mixed slate of polymers derived from bio-based, chemically-recycled, and mechanically-recycled feedstocks. And while the latter two routes may be preferred by some resin producers, pressure from brand owners and consumers will ensure that bio-based polyolefins play a notable role in achieving sustainability targets.

The European Commission’s Packaging and Packaging Waste Directive (PPWD) in its current form is a potential complicating factor to market growth for bio-polyolefins, according to Moore. “The Commission has essentially signaled its preference for C14 assay over mass balance as the preferred means of measuring bio content, and added that bio-based plastics should target durable applications such as pipe and automotive, thereby functioning as carbon sinks. I don’t believe this is a stance that will be acceptable to bio-polyolefin suppliers given their investment in the mass balance approach.”

On the bio-polyolefin supply side, the main incumbent supplier ��— Braskem — is being joined by a stable of European, Japanese, and Korean companies, with Dow Chemical also increasing its presence via production assets in Europe. “Bio-polyolefins are major components of Korean and Japanese suppliers’ sustainability strategies, and they will have ready access to export-oriented markets in Asia Pacific,” said Moore. “In fact, by 2032, we expect the Asia-Pacific region to overtake Europe in consumption of bio-polyolefins.”

Bio-polyolefin suppliers also need to ensure they can secure sufficient bio-feedstocks to polymerize their products for the market, according to Moore. “Most bio-refineries focus on production of bio-fuels, with bio-naphtha being a lower priority by-product,” noted Moore.

Established in June 2021 in Singapore by plastics industry market research veteran Stephen Moore and partners, MLT Analytics applies machine learning (ML) technology and artificial intelligence (AI), augmented by extensive hands-on industry knowledge, to develop robust, reliable forecasts. Commodity, specialty and engineering plastics and elastomers, petrochemical feedstocks and products, and specialty chemicals and additives are among the areas of expertise. Moore is a longtime contributor to PlasticsToday covering the automotive sector and Asia Pacific.

You May Also Like