Environmental concerns are raising the profile of biodegradable plastic, which is forecast to grow to more than $6 billion in market size by 2023. As researchers continue to develop new materials and improve properties, biodegradable polymers are poised to revolutionize everything from food packaging to medical devices.

October 20, 2020

Dr. Raj Shah, Mr. Rui Chen, Ms.Hillary Wong

Demand for biodegradable polymers has been rising as a result of environmental concerns regarding the use of nonrenewable materials. Styrofoam and other plastics are among the most produced materials used for packaging and other applications. Such materials cause land and water pollution and have been linked in some studies to health problems in humans and animals. In order to solve these issues, scientists and engineers are diligently innovating and creating new biodegradable polymers. They are widely used in different fields and applications, such as packaging, agriculture, and healthcare. Different kinds of materials used to develop biodegradable polymers are being researched and tested by scientists and engineers to evaluate their effectiveness, safety, and environmental sustainability. Biodegradable polymers are being integrated into society and becoming a norm in plastic packaging that promotes a healthy, sustainable lifestyle. Indeed, it is becoming the next big thing: The market size of biodegradable plastics is expected to grow to $6.12 billion by 2023, according to a business report from MarketsandMarkets.

When developing new biodegradable polymers, researchers consider the biodegradable behavior and antimicrobial activity of the materials. Various types of materials being used to create biodegradable polymers are made through different processes. For example, polylactic acid (PLA) is a biodegradable polyester made from lactic acid through the process of fermentation of renewable crops, such as corn and sugar beets. Polycaprolactone (PCL), another material that is often used, is a biodegradable polyester that has good thermal processability, a low melting point, and low viscosity that is synthesized through polymerization of Ɛ-caprolactone. PCL is usually blended with other polymers to increase stress resistance and adhesion. Other materials used to develop biodegradable polymers include polyhydroxyalkanoates (PHA) and polyhydroxy butyrate (PHB). These materials are commonly found in food packaging.

Biodegradable polymers are also developed by the amalgamation of individual components to create a new material. For example, starch and polyolefins can be blended to create biodegradable packaging. The synthesis process requires either cast or blown film. The polyolefins aid in improving the mechanical properties of the biodegradable material while high amounts of starch — as much as 60% in mass concentration — are used to fashion the material into something biodegradable.

Another prominent material used in biodegradable polymers is cellulose, a natural, biobased polymer that is obtained from trees and plants. It is a tough polymer with desirable tensile strength and elongation properties. In addition, cellulose can be blended with other polymers to create a substantial biodegradable material. The latest developments ostensibly involve biobased polymers with improved performance and properties. Nature Works LLC has developed new PLAs with better thermal and mechanical properties. Other developments include new polyamides, polyesters, and PHAs with a distinct differentiation in their properties compared with existing biobased polymers.

Integrating antimicrobial technology in biodegradable polymers

Different kinds of materials and techniques are used to create a diverse cohort of biodegradable polymers. Conventional polymers are made from petroleum resources, which render them resistant to degradation. Biodegradable biomaterials have undergone advances in the substances used to create them and the synthesis of the polymers with certain properties for specific biomedical applications, as noted in “Current Development of Biodegradable Polymeric Materials for Biomedical Applications” published in Drug Design, Development and Therapy. Biodegradable biomaterials research and development has had an impact on temporary prosthetics, 3D porous scaffolds for tissue engineering, and drug-delivery systems.

|

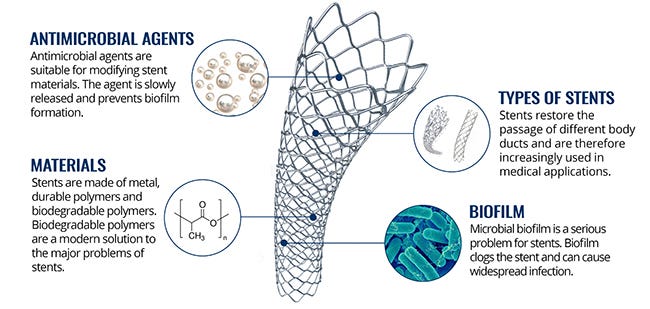

Graphic courtesy Nanomaterials 2019, 9(11), 1548; https://doi.org/10.3390/nano9111548. |

Biodegradable polymers can also incorporate antimicrobial technology. Antimicrobial food packaging extends preservation and imparts a longer shelf life to the product. Antimicrobial packaging is produced by adding bioactive agents into the packaging compounds. The bioactive agents are applied by coating the surface of the package or creating a film utilizing antimicrobial polymers. The bioactive agents can be used with materials mentioned earlier, such as PLA, PHB, and starch.

Biobased polymers are currently trending in research and development for alternatives to existing polymers. Researchers are delving into new materials that can be manufactured to offset the use of petroleum-based polymers. Biobased polymers are comprised of renewable resources. These polymers currently hold a small fraction — less than 1% — of the plastic market. Biobased polymers are formulated via the bacterial fermentation process, which synthesizes monomers from renewable sources derived from agricultural crops, fatty acids, ligno-cellulosic biomass, and organic waste. Natural biobased polymers are intrinsically found in different proteins and nucleic acids such as collagen.

In the improvement of biodegradable polymers, downsides like weak mechanical properties, low electrical and thermal properties, and narrow processing windows need to be dealt with. One possibility is to composite them with nanofillers. Composites have different applications and properties based on the surface area and aspect ratio of the material. Composites enhance the properties of biodegradable polymers while remaining eco-friendly. Biodegradable composite materials have various applications, such as artificial joints, drug-delivery systems, biofilms, and food packaging. Biobased hybrid nanocomposites are used in tandem with biobased polymers to enhance the natural fibers of the polymers as well as improve their overall performance and durability.

The latest anticipated breakthroughs in the plastics industry involve making plastic more biodegradable while maintaining its strength and durability in order to compete with generic plastics. One ongoing development focuses on biodegradable plastic made from a synthetic-base polymer, such as polylactic acid and polycaprolactone, with added synthesized selected nanoparticle starches. Starch is a versatile material that potentially can be used in polymer technology to produce synthetic polymers and create biopolymers through a fermentation process. When mixed and gelatinized with different materials, starch creates distinct properties, such as bindability and gel-ability, which are a boon for an array of applications, as well as an asset to biodegradation.

From lightweighting to active food packaging

Metal replacement in automotive applications is another hot topic in the biodegradable plastics space. Engineered biodegradable plastic parts contribute to lightweighting, which reduces fuel consumption. Other sectors, such as textiles and consumer goods, also use biodegradable plastics. Biodegradable plastics production is steadily growing, with an estimated 2.6-million tons forecast to be produced by 2023 (65% of which is to be used for packaging). It is also anticipated that by 2023, polyethylene furanoate will be introduced to the market, which could become the new novelty in biobased plastic for beverage bottles.

Biodegradable films and coatings for active food packaging are also being developed. Essential oil compounds are being researched for films and coatings. The research into essential oils is prompting interest in other natural additives. For example, the effectiveness of cellulose acetate in biodegradable plastics has been studied, including the material’s strength, resistance, moldability, fabrication versatility, and electric conductivity. Biodegradation tests were conducted to discern how cellulose acetate would help biodegradation in flax fibers and cotton linters. Test results show that cellulose acetate loses weight over time, shedding around 32 to 41% of its weight in two weeks in various temperatures. These results conclude that cellulose acetate in both flax fibers and cotton linters is biodegradable by thermophilic microorganisms. Cellulose acetate is also used to make photographic films, filtration membranes, and fibers, further exhibiting its functionality in the development of biodegradable plastics.

Additionally, synthetic polymer-ceramic composites have been researched for their use in biomedical applications, specifically for the treatment of bone-related diseases and disorders. Ceramics are a natural fit for this type of application because of their biocompatibility and construction that is similar to bone. Synthetic polymers were chosen since natural polymers such as collagen have shown issues such as instability and subpar biodegradability. Various additive manufacturing methods such as stereolithography, selective laser sintering (SLS), and bioprinting can be used for the production of such composites that can function as an implant or for the treatment of bone-related diseases. The specific method, however, is dependent on the specifications of the composite material.

Biodegradability improves polymer electrolyte performance

Recent studies have discovered that the use of biodegradable polymers in the creation of polymer electrolytes resulted in higher performance capabilities compared with nonbiodegradable counterparts. These improved capabilities of the solid electrolytes include ionic conductivity and stability. The thin-film polymer is produced by the mixture of a polymer solution and salt solution in a common solvent, followed by a mixing with additives and, later, evaporation of the solvent. The ionic conductivity and mechanical property of the electrolytes are affected by multiple factors, among which are the type of polymers used and the variety of ionic salts applied. By blending the polymers, one material allows for a specific property of the electrolyte while the other enables a different property, such as ion transportation and mechanical strength.

A new product based on biodegradable polymers filters drinking water while adding essential minerals. The dual feature purifies the water and supplements it with minerals and salts, enabling the water to provide key nutrients even when they are not initially available. The filter membranes are made of two layers: A porous layer for filtering is made from biodegradable polymers; the other layer made from fiber composites adds salts and minerals. The fibers are made from specific plants, such as banana and spinach, which are chosen based on their mineral and salt content in order to fulfill nutritional requirements.

Ongoing research into biodegradable plastics is exploring the various permutations of biodegradable nanocomposites that can be employed in the industry and the development of new biodegradable nanocomposites with improved mechanical and separation properties and that can withstand hot temperatures.

Nanofiller biodegradable composite materials are being researched along with the methods used to synthesize them. The different methods used to prepare the nanofiller-composite materials depend on the materials that are being used as nanofillers. For example, nanocellulose biodegradable composites undergo solvent casting and melt processing, which helps add nanocellulose into the polymer. The method will determine the type of polymer that will be used. Solvent casting uses water-soluble polymers, polymer emulsions, and water insoluble polymers. Melt processing is commonly used to melt a material by adding plasticized material to a machine. Nanoclay-biodegradable composites are another material applied in biodegradable plastics. The methods used to synthesize nanoclay-biodegradable are polymer solution embedding, in-situ polymerization, and melt embedding. Carbon nanotubes are also explored as a function of nanofillers. Carbon nanotubes enhance biodegradable composites by affecting the molecular structure and degree of dispersion. When the carbon nanotubes are uniformly dispersed, the composites can become stronger and more durable.

Biodegradable plastics have an exciting potential to change the way people live their lives through mindful sustainability. Biodegradable polymers can go beyond food packaging and revolutionize furniture, batteries, toothbrushes, diapers, phones, computers, and more. Researchers continue to make progress in developing biodegradable materials that adhere to industry and safety guidelines and are affordable, renewable, and can compete with conventional plastics in terms of performance and durability while being eco-friendly. The world can look forward to biodegradable polymers bringing a big change to how every product is made.

About the authors

|

Raj Shah, PhD |

Dr. Raj Shah currently is a director at Koehler Instrument Co., a manufacturer of petroleum testing instruments, and an Adjunct Professor at the Dept. of Material Science and Chemical Engineering at State University of New York (Stony Brook, NY). He has been an active ASTM member for the last 25 years. He has held numerous leadership positions within various ASTM committees and is a three-time recipient of the ASTM Award of Excellence and the ASTM Eagle Award. Shah holds a PhD in Chemical Engineering from Penn State University, and a Fellow designation from the Chartered Management Institute, London. Dr. Shah recently co-edited a reference bestseller, Fuels and lubricants handbook, published by ASTM.

He is an elected Fellow by his peers at the Energy Institute, NLGI, STLE, IChemE, INSTMC, AIC, CMI, and the Royal Society of Chemistry. A Chartered Petroleum Engineer, he was recently elected Fellow by the Institution of Chemical Engineers, UK. Dr. Shah was also recently honored with an esteemed engineer designation by Tau Beta Pi, the highest engineering honor society in USA. More information on Shah can be found here.

He can be reached at [email protected].

Ms. Hillary Wong and Mr. Rui Chen are Chemical Engineers from Stony Brook University, where Dr. Shah is the Chair of the External Advisory Board of directors. They are also part of a thriving internship program at Koehler Instrument Co. in Holtsville, NY.

You May Also Like