- Blow Molding

- Packaging

- End Markets

- Extrusion: Pipe & Profile

- Extrusion: Film & Sheet

- Workforce & Training

The maker of blow-molding machinery conducted a virtual tour with machine demonstrations, presentations by Bekum employees, and a walk-through of its Apprenticeship Training Center.

October 2, 2020

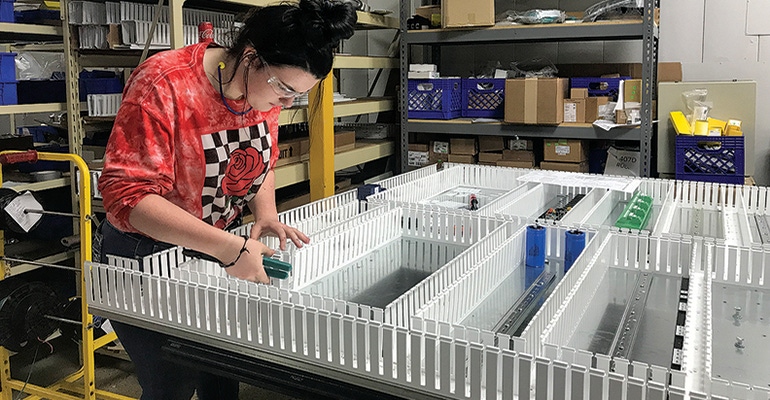

Last year, Bekum America welcomed more than 200 students to tour its facility in Williamston, MI, on Manufacturing Day to see its blow-molding machinery in action and learn about career opportunities. Live visits are not an option this year because of COVID-19, so Bekum America conducted a virtual tour that included machine demonstrations, presentations by Bekum employees, and a walk-through of the Apprenticeship Training Center.

“We are excited to welcome so many students to join us in celebrating Manufacturing Day in a virtual environment this year,” said Steve London, Bekum President and COO. “We plan on sharing the many opportunities and experiences of modern manufacturing and showing students the benefits of joining our industry. Despite limitations associated with COVID-19, we are confident that students will get a great overview of our facility and our industry.”

As Clare Goldsberry notes in her article, “Manufacturing Day 2020 Celebrates an Essential Sector,” the annual event held on the first Friday of October honors manufacturers and showcases the manufacturing sector’s critical role in the US economy. “That was never made clearer than this year, when a global pandemic revealed just how crucial US manufacturing is across industry sectors,” writes Goldsberry.

Manufacturing Day is also designed to correct misperceptions about the industry, stressed Bekum America. Notably, by visiting modern manufacturing facilities young people can see first-hand that these plants are far-removed from the Dickensian clichés of dirty and unsafe factories where workers resemble beasts of burden. On the contrary, advanced manufacturing is powered by automation, virtual reality, 3D printing, and many other advanced technologies. Bekum America also reports that manufacturers have the highest job retention rates in the private sector and that 90% of the workforce have medical benefits.

Nevertheless, the skills gap persists, and manufacturers continue to struggle finding employees to fill vacant positions as baby boomers retire en masse. One way that manufacturers are countering this trend is through partnerships with local educational institutions.

Bekum’s global headquarters is in Germany, where apprenticeship programs are commonplace and play a key role in fostering a steady stream of highly skilled workers. Bekum America, which was established in 1979, has developed its own apprenticeship program, working with various school districts, career centers, and local area high schools to identify and recruit students. Each apprentice must complete 8,000 hours of training and complete approximately 60 credit hours at Lansing Community College, working toward an associate degree.

Bekum established its Apprenticeship Program in 1994. In May of 2001, according to the Department of Labor, Bekum America graduated the two youngest, active journeymen in the United States. Approximately 50% of Bekum's manufacturing workforce have graduated from the apprenticeship program or are currently registered in the program, according to the company.

About the Author(s)

You May Also Like