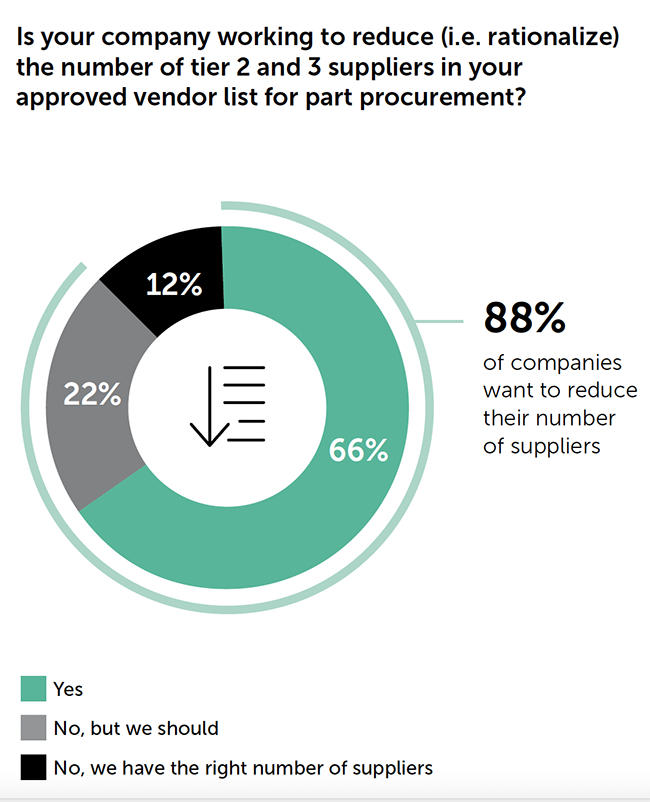

An overwhelming 88% of manufacturers want to thin their supplier pool, according to a survey by on-demand digital manufacturing company Fictiv.

June 6, 2022

Disruptions to the global supply chain driven by the pandemic in 2020 persist, and manufacturers continue to address the cascading events in a variety of ways, according to a 2022 manufacturing survey conducted by on-demand digital manufacturing company Fictiv.

Improving supply-chain visibility and increasing customer satisfaction top the list of priorities of survey respondents. Fifty-nine percent said improving supply-chain visibility was their single most important business priority in 2022, while 45% chose improving customer satisfaction. This indicates that companies are using recent supply-chain disruptions as an opportunity to address their business fundamentals, Fictiv said.

|

In fact, 88% of manufacturing companies surveyed said they want to streamline production by using fewer suppliers. In addition, a majority said they are working toward better coordination with suppliers. In particular, they are looking for tighter integration with fewer suppliers in order to gain control and predictability over their supply chains, which they see as key to addressing increasing customer demand. Only 12% of respondents said they have the right number of suppliers.

More than 90% of companies are using or implementing some type of digital manufacturing technology. The survey defines digital manufacturing as supply chain analytics and visualization platforms, on-demand manufacturing platforms, the industrial internet of things, intelligent asset management, product lifecycle management, advanced industrial robotics, virtual or augmented reality, and digital twins.

Of those digital manufacturing technologies, 94% of companies surveyed are using or implementing supply-chain analytics and visualization, making it the most widely used digital technology.

A bedrock of manufacturing, productivity continues to be a high priority. Companies aim to improve productivity by better integrating remote workforces and improving collaboration between their engineering and supply chain teams.

Some 75% of companies surveyed see room for improvement in the way their engineering and supply-chain teams collaborate. And 72% of them reported that their engineers routinely spend 10% or more of their time on part procurement. How much faster could engineers innovate and develop new products if they got that time back, the survey asks.

The remote workforce is here to stay, according to the survey. Half of respondents said they have more remote employees as a result of COVID-19, which is a slight drop from the 2021 survey. Ensuring the smooth flow of digital information throughout organizations is key to having successful remote employees, Fictiv said. The ongoing presence of distributed teams makes the technologies that connect those teams critical to their success.

Information security has surfaced as a risk, as the adoption of remote workforces and new digital manufacturing technologies become more widespread. More than 90% of respondents are using or implementing digital manufacturing technologies, and 97% of leaders are concerned about digital security.

The Fictiv 2022 State of Manufacturing Report was based on an online survey conducted from April 26 to May 3, 2022. A total of 234 individuals from 234 companies responded. Participants included senior decision makers who work in supply chain, engineering, research and development, technology, or business leadership roles at companies that manufacture medical devices, robotics, automotive, aerospace, or consumer electronics products. Many of those companies that design, develop, and deliver physical products across each of these industries produce plastic materials and employ plastics manufacturing processes, including 3D printing and injection molding.

Fictiv operates a globally dispersed digital manufacturing system that’s designed to deliver custom mechanical parts on demand. Its portfolio of manufacturing services includes 3D printing, CNC machining, urethane casting, and injection molding. Fictiv said it has manufactured more than 19 million parts in the last eight years.

About the Author(s)

You May Also Like