In mid-2011, BASF (Ludwigshafen) took another step forward on the road to plastic applications in automobile bodies and chassis by establishing its cross-divisional, multi-material Lightweight Composite Team.

April 13, 2012

In mid-2011, BASF (Ludwigshafen) took another step forward on the road to plastic applications in automobile bodies and chassis by establishing its cross-divisional, multi-material Lightweight Composite Team. This team is simultaneously investigating the potential that three plastic matrix systems, epoxy resin, PUR and polyamide, hold for continuous-fiber reinforcement in resin injection processes suitable for mass production, including in particular resin transfer molding (RTM).

|

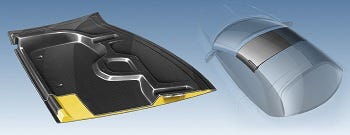

Conceptual roof system is 40% lighter than an aluminum equivalent. |

These thermoplastic composites can be formed, recycled and welded. Apart from add-on parts like doors, tailgates and roof modules, potential applications also include highly loaded structural automotive parts. Companies such as Evonik (Essen, Germany) are working on similar material systems.

A first demonstrator component based on BASF's multi-faceted materials for RTM processing is the conceptual study of a multi-segmented convertible roof module in which a polyurethane foam core is sandwiched between carbon-fiber reinforced cover layers.

The layer in the core of the demonstrator sandwich plate is a closed-cell structural PUR foam branded ElastolitD. With its low bulk density it acts as a spacer between the skins of the laminate, ensuring extremely high component stiffness. It also provides the roof module with good insulating properties. At a total weight of 2.6 kilograms, the roof segment based on the fiber-reinforced composite sandwich concept reduces weight by more than 40 % compared to an aluminum, and by more than 60 % compared to a steel structure.-[email protected]

About the Author(s)

You May Also Like