EcoPaxx, the biobased polyamide produced by Royal DSM (Heerlen, Netherlands), the global life sciences and material sciences company, will soon be scaling new heights. Sports equipment manufacturer Salomon (Annecy, France) has chosen EcoPaXX for the Edging Chassis of its innovative new mountaineering shoe.

April 16, 2015

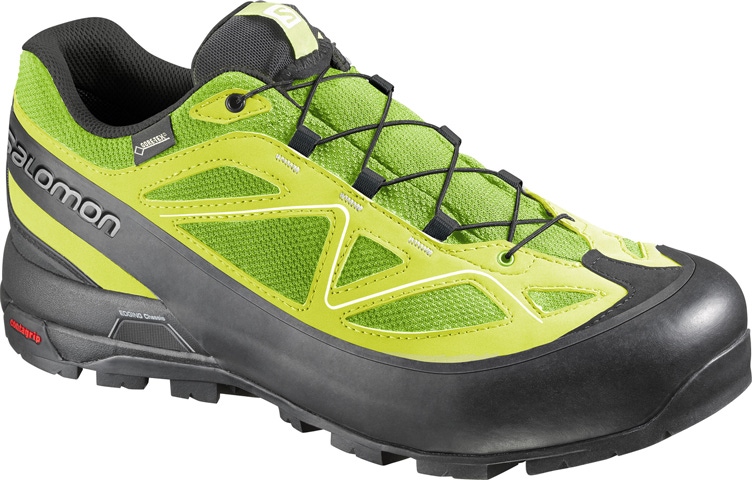

EcoPaxx, the biobased polyamide produced by Royal DSM (Heerlen, Netherlands), the global life sciences and material sciences company, will soon be scaling new heights. Sports equipment manufacturer Salomon (Annecy, France) has chosen EcoPaXX for the Edging Chassis of its innovative new mountaineering shoe.

Comfortable and lightweight, Salomon's X Alp range of mountaineering shoes are designed with a so-called Edging Chassis, patented by Salomon. The feature is a special plate built into the sole with a sophisticated design that combines two opposites, flexibility and stiffness. The Edging Chassis provides stability for the foot in the transverse direction—to provide good grip on narrow ledges—but also allows enough flexibility in the longitudinal direction to accommodate the natural flexing of the foot.

Comfortable and lightweight, Salomon's X Alp range of mountaineering shoes are designed with a so-called Edging Chassis, patented by Salomon. The feature is a special plate built into the sole with a sophisticated design that combines two opposites, flexibility and stiffness. The Edging Chassis provides stability for the foot in the transverse direction—to provide good grip on narrow ledges—but also allows enough flexibility in the longitudinal direction to accommodate the natural flexing of the foot.

"X Alp shoe expresses the cutting edge of light mountaineering," said Aude Derrier, Project Manager in the Materials Footwear Department of Global Footwear at Amer Sports, Salomon's mother company.

Salomon, however, needed a material that could offer the necessary mechanical properties. The company turned to DSM for help.

"Salomon, Amer Sports Group and DSM have a long partnership history and have worked together on other challenging EcoPaXX projects like high-end snowboard bindings," said Derrier. "We were confident that DSM could help us to create our new generation of mountaineering shoes, and our confidence has been justified."

EcoPaXX provided the right combination of mechanical properties and toughness, and offered the added advantage of easy processability. The intrinsic fast crystallization of EcoPaXX grades helps to ensure short injection-molding cycle times. Moreover, the Edging Chassis required a material with excellent flow characteristics, as the design called for the use of a mold with multiple gating, which creates multiple weld lines. High weld-line strength was, therefore, essential.

EcoPaXX retains its properties at the very low temperatures typical of mountain environments, and has reduced moisture uptake, despite being a polyamide. Moreover, it is very suitable for injection molding and is certified as carbon neutral from cradle to gate. For Salomon, it became the material of choice for the highly engineered, light chassis on three models of the new X Alp range of mountaineering shoes: the X Alp GTX, X Alp MTN GTX and X Alp PRO GTX.

According to Derrier, models with the patented EcoPaXX Edging Chassis can be used from lower flanks of the mountain as well as for approach. The innovation is the result of more than two years of intensive development and field tests with professional guides, rescue teams and athletes. "It is a pure expression of Salomon's approach to product innovation and its mountain heritage," said Derrier.

About the Author(s)

You May Also Like