Saint-Gobain Performance Plastics is bringing to market a new silicone extrusion technology, called Compass, which targets a variety of medical tubing applications, including ophthalmic pumps, enteral feeding, and intravenous therapy."Compass Technology is about enhancing our ability to improve product performance by focusing on the both the raw material and an improved manufacturing process," Aaron Updegrove, marketing manager, Saint-Gobain Performance Plastics (Worcester, MA), told PlasticsToday.

June 20, 2012

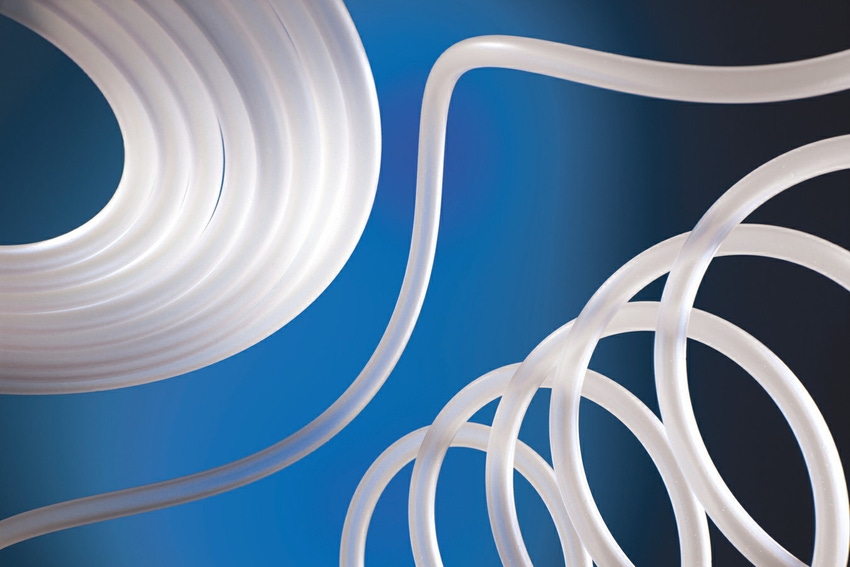

Saint-Gobain Performance Plastics is bringing to market a new silicone extrusion technology, called Compass, which targets a variety of medical tubing applications, including ophthalmic pumps, enteral feeding, and intravenous therapy.

"Compass Technology is about enhancing our ability to improve product performance by focusing on the both the raw material and an improved manufacturing process," Aaron Updegrove, marketing manager, Saint-Gobain Performance Plastics (Worcester, MA), told PlasticsToday.

|

Improved process control is one of the attributes of Compass Technology. |

The process starts with a customer dialogue to develop a custom silicone compound. "We can target physicalproperties as tear strength, modulus, compression set, durometer, tensile strength and elongation," Updegrove said. The material is then run on Saint-Gobain's newly developed tubing extrusion process.

"While the specifics of the Compass Technology extrusion process remain proprietary, in broad terms, we have optimized the manufacturing to reduce variation and maintain the tubing consistency from lot to lot."

A closed-loop system automatically makes adjustments to reduce variation from production run to production run while monitoring manufacturing data. The data is captured and available to expedite product validation for medical device OEMs.

One of the targets of the approach is to deliver products that meet expanding requirements for purity and low extractables.

As part of Compass Technology, Saint-Gobain Performance Plastics is also developing an advanced modeling platform for pump and fluid handling systems. The goal is to provide insight into the effect of variables on system accuracy. From physical dimensions to dynamic properties of the material, it is hoped the model can function as a predictor for new designs.

"Although we have worked with external equipment and raw material suppliers, the uniqueness of the capability of Compass Technology is really the result of an intense internal R&D effort," Updegrove told Plastics Today.

Saint-Gobain has developed custom formulations for customer before, but the processing aspect is new technology.

"To bring Compass Technology to fruition, we invested heavily in equipment and technology related to both the material formulation and the extrusion process. With the financial backing of Saint-Gobain, we have plans to expand the capacity in North America, and sites all over the world."

You May Also Like